Audi Q7: Engine Control Module

Overview - Engine Control Module

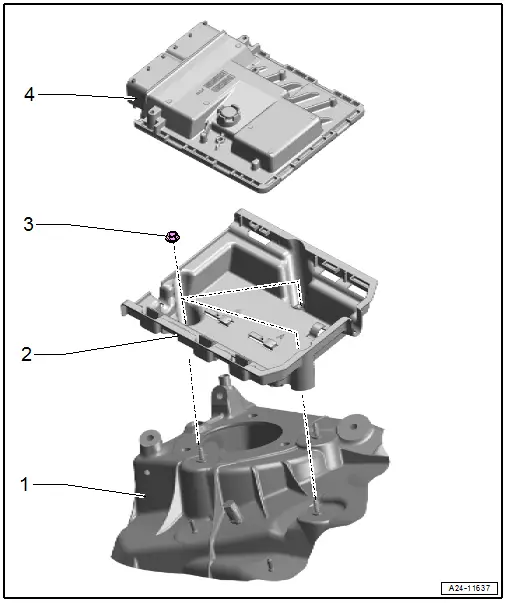

1 - Suspension Strut Tower

2 - Mount

- For the Engine Control Module -J623-

3 - Nut

- 9 Nm

4 - Engine Control Module -J623-

- Removing and installing. Refer to → Chapter "Engine Control Module -J623-, Removing and Installing".

Engine Control Module -J623-, Removing and Installing

Removing

- Switch off the ignition.

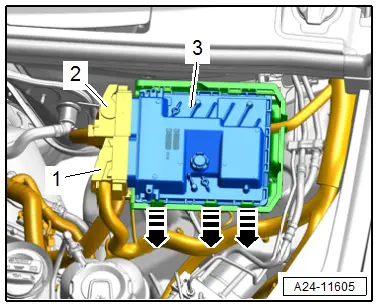

- Disconnect the connectors -1 and 2-.

- Release the catches in direction of -arrows- and remove the Engine Control Module -J623-.

Installing

Install in reverse order of removal and note the following:

- If the Engine Control Module -J623- was replaced. Refer to Vehicle Diagnostic Tester, 01 - Replacing control module.

- If the Engine Control Module -J623- was replaced. Refer to Vehicle Diagnostic Tester, 01 - Adaptation Values, Adapting after Component Replacement.

- Start the selected program and follow the instructions in the display of the Vehicle Diagnostic Tester.

Tightening Specifications

- Refer to → Chapter "Overview - Engine Control Module"

Special Tools

Special tools and workshop equipment required

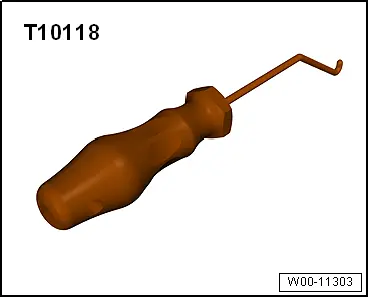

- Elbow Assembly Tool -T10118-

- Injector/Combustion Chamber Seal Tool Set -T10133C-

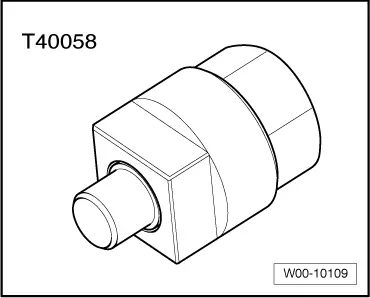

- Crankshaft Socket -T40058-

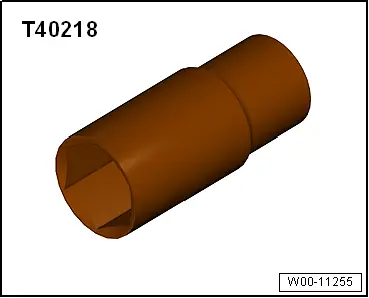

- Socket - 27mm -T40218- or 27 mm socket, commercially available

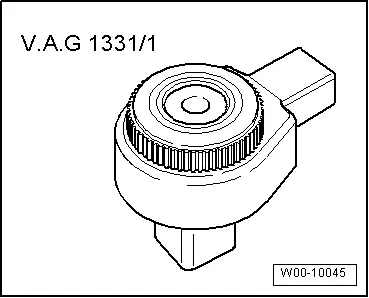

- Torque Wrench 1331 Insert - Reversible Ratchet -VAG1331/1-

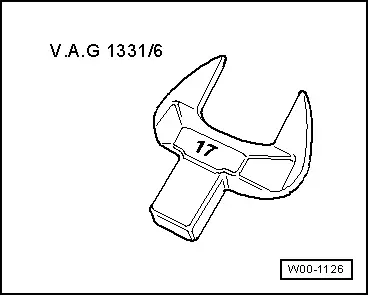

- Torque Wrench 1331 Insert - Open Jaw - 17mm -VAG1331/6-

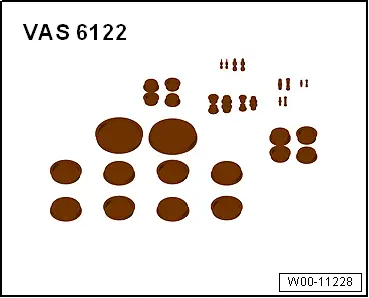

- Engine Bung Set -VAS6122-

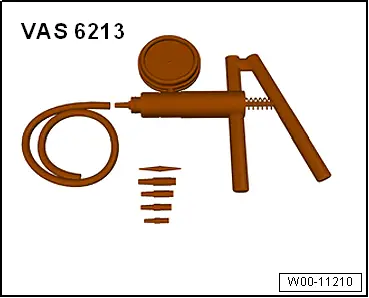

- Hand Vacuum Pump -VAS6213-

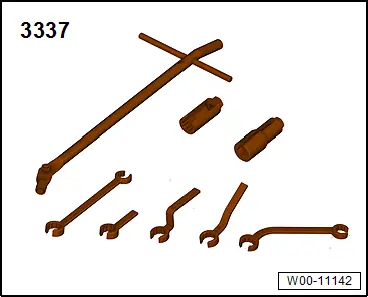

- Ring Wrench 7-Piece Set -3337-

- Torque Wrench 1331 5-50Nm -VAG1331-

- Torque Wrench 1331 Insert - Ring Wrench - 11mm & 17mm -VAG1331/2-

- Torque Wrench 1331 Insert - Open Ring Wrench - 14mm -VAG1331/8-