Audi Q7: Control Arm Ball Bearing, Replacing

Control Arm Ball Bearing, Replacing, Wheel Bearing Housing Side

Special tools and workshop equipment required

- Press Plate -VW402-

- Press Piece - Multiple Use -VW412-

- Press Piece - 42mm -VW516-

- Press Piece - Reverse Gear Syncro -3296-

- Assembly Paste -G 052 109 A2-

Procedure

- The control arm is removed. Refer to → Chapter "Control Arm, Removing and Installing".

Pressing out the Bonded Rubber Bushing

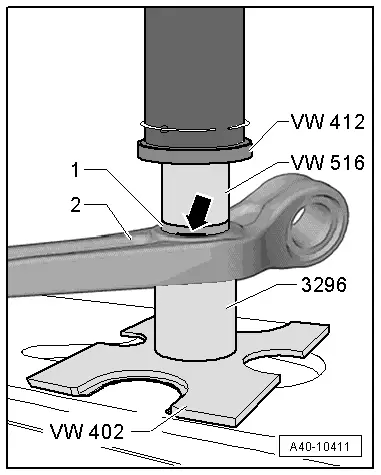

- Mark the press-in depth of the bonded rubber bushing -1- for example using a waterproof felt-tip pen -arrow-.

- Mount the special tools as shown.

Note

Note

Hold the control arm firmly in position while pressing bonded rubber bushing out and in.

- Press out the bonded rubber bushing from the control arm -2-.

Installing the Bonded Rubber Bushings

- Transfer the marking for the press-in depth from the old bonded rubber bushing to the new one.

- Thinly coat the bonded rubber bushing with the Assembly Paste -G 052 109 A2-.

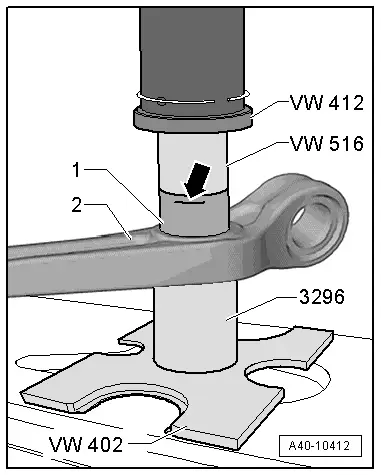

- Insert the bonded rubber bushing -1- in the control arm -2-.

- Mount the special tools as shown.

- Press the bonded rubber bushing in the control arm, at the same time do not tilt it.

- Pay attention to the mark -arrow- for the press-in depth.

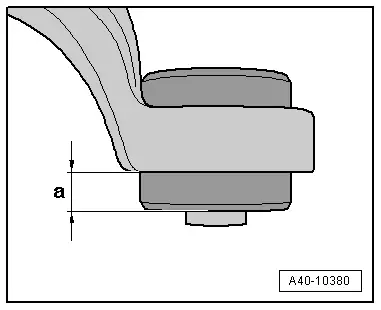

- Check the press-in depth of the bonded rubber bushing -1- in the control arm -2-.

- Specified value: dimension -a- = dimension -b-.

- If the values are different, press in the bonded rubber bushing again.

Control Arm Ball Bearing, Replacing, Subframe Side

Special tools and workshop equipment required

- Press Plate -VW402-

- Press Piece - Multiple Use -VW412-

- Press Piece - Reverse Gear Syncro -3296-

- Puller - Differential Bearing -T40032-

- Assembly Paste -G 052 109 A2-

Procedure

- The control arm is removed. Refer to → Chapter "Control Arm, Removing and Installing".

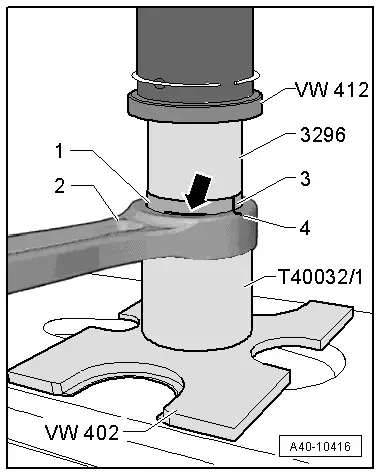

Pressing out the Bonded Rubber Bushing

- Mark the press-in depth -arrow- and the installation position -3 and 4- on the bonded rubber bushing -1- with for example a waterproof felt-tip pen as shown.

- Mount the special tools as shown.

Note

Note

Hold the control arm firmly in position while pressing bonded rubber bushing out and in.

- Press out the bonded rubber bushing from the control arm -2-.

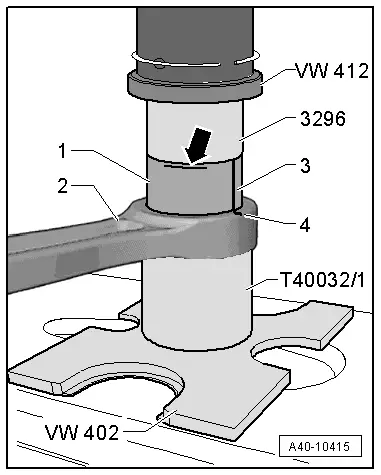

Installing the Bonded Rubber Bushings

- Transfer the marking for the press-in depth from the old bonded rubber bushing to the new one.

- Thinly coat the bonded rubber bushing with the Assembly Paste -G 052 109 A2-.

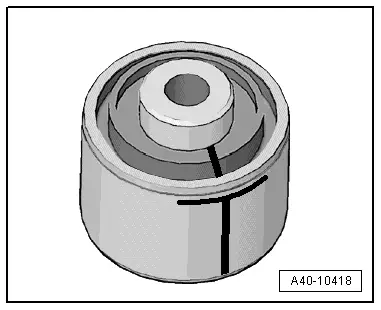

- Insert the bonded rubber bushing -1- in the control arm -2- and align to the mark -3- to -4-.

- Mount the special tools as shown.

- Press the bonded rubber bushing in the control arm, at the same time do not tilt it.

- Pay close attention to the press-in depth mark -arrow-.

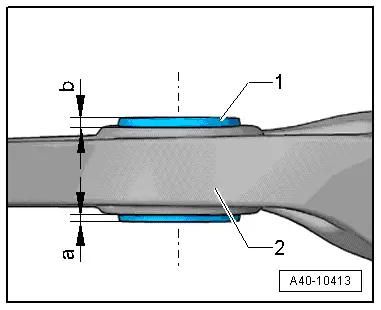

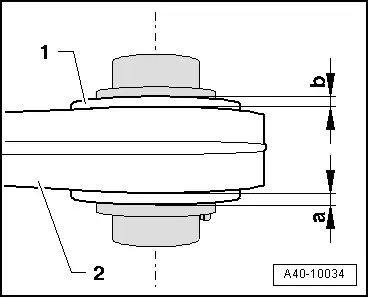

- Check the press-in depth of the bonded rubber bushing -1- in the control arm -2-.

- Specified value: dimension -a- = dimension -b-.

- If the values are different, press in the bonded rubber bushing again.

Ball Joint, Removing and Installing

Special tools and workshop equipment required

- Torque Wrench 1332 40-200Nm -VAG1332-

- Torque Wrench 1332 Insert - Ring Wrench - 21mm -VAG1332/7-

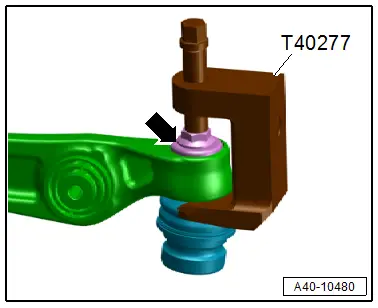

- Ball Joint Splitter -T40277-

Removing

- The control arm is removed. Refer to → Chapter "Control Arm, Removing and Installing".

WARNING

WARNING

Risk of injury from falling components!

When pressing off, the ball joint loosens abruptly from the control arm. Secure the Ball Joint Splitter -T40277-.

- Clamp the control arm in a vise with protective covers.

- To protect the threads remove the nut -arrow- on the joint pin of the ball joint until it is flush with the threads of the joint pin.

- Press off the ball joint with the Ball Joint Splitter -T40277- from the control arm, at the same time do not damage the CV boot.

- Then remove the nuts and the ball joint, to do so counterhold on the joint pin with a TX 40 socket.

Installing

Install in reverse order of removal.

Guide Link Bonded Rubber Bushing, Removing and Installing

Special tools and workshop equipment required

- Press Plate -VW402-

- Press Piece - Multiple Use -VW412-

- Bearing Installer - Ball Joint/Bushing/Bearing 2 -VW459/2-

- Bearing Installer - Wheel Bearing -3144-

- Pneumatic Hydraulic Press -VAS6654-, not illustrated

- Installation Lubricant -G 294 421 A1-. Refer to the Parts Catalog.

Pressing out the Bonded Rubber Bushing

- The guide link is removed. Refer to → Chapter "Guide Link, Removing and Installing"

- Mark the press-in depth -arrow- of the bonded rubber bushing -1- for example using a waterproof felt-tip pen.

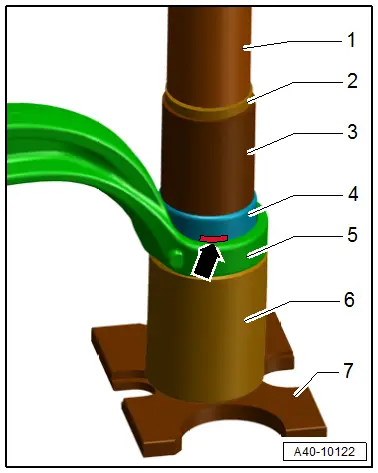

- Mount the special tools as shown.

1 - Pneumatic Hydraulic Press -VAS6654- Punch

2 - Press Piece - Multiple Use -VW412-

3 - Bearing Installer - Ball Joint/Bushing/Bearing 2 -VW459/2-

4 - Bonded Rubber Bushing

5 - Guide link

6 - Bearing Installer - Wheel Bearing -3144-

7 - Press Plate -VW402-

Note

Note

Hold the guide link firmly in position while pressing bonded rubber bushing out and in.

- Remove the bonded rubber bushing from the guide link.

Installing the Bonded Rubber Bushings

- Transfer the marking for the press-in depth from the old bonded rubber bushing to the new one.

- Coat the new bonded rubber bushings thinly with Installation Lubricant -G 294 421 A1-.

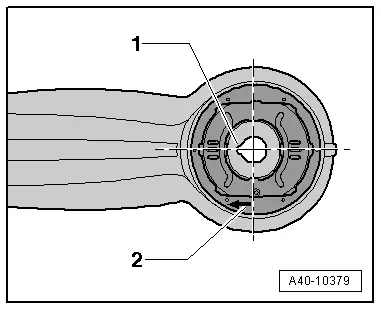

Bonded rubber bushing installation position:

- The notch -1- is on the steering axle and faces inward to the guide link.

- The arrow -2- points inward to the guide link.

- Install the bonded rubber bushing in the guide link. Pay attention to the installed position

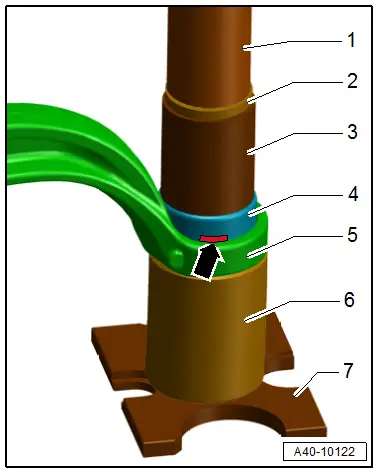

- Mount the special tools as shown.

1 - Pneumatic Hydraulic Press -VAS6654- Punch

2 - Press Piece - Multiple Use -VW412-

3 - Bearing Installer - Ball Joint/Bushing/Bearing 2 -VW459/2-

4 - Bonded Rubber Bushing

5 - Guide link

6 - Bearing Installer - Wheel Bearing -3144-

7 - Press Plate -VW402-

- Press the bonded rubber bushing in the guide link, at the same time do not tilt it.

- Pay attention to the mark -arrow- for the press-in depth.

- Check the depth -a- of the bonded rubber bushing inside the guide link.

- Dimension -a- = 23 mm.

- If the value is not reached, press in the bonded rubber bushing again.