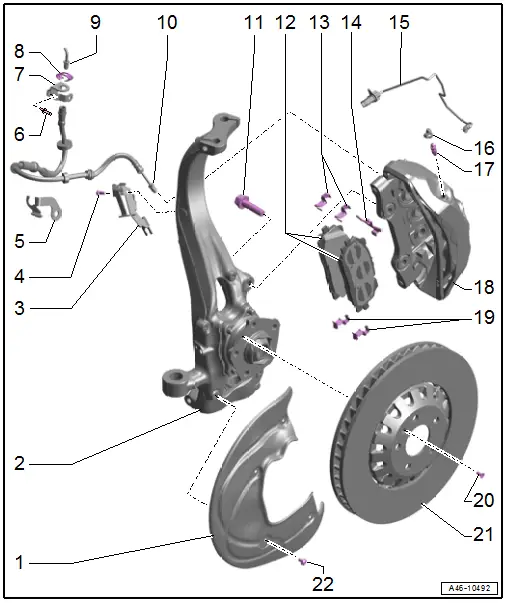

Audi Q7: Overview - Front Brakes

Audi Q7 (4M) 2016-2026 Workshop Manual / Chassis / Brake System / Mechanical Components / Overview - Front Brakes

1 - Brake Shield

- Refer to → Chapter "Brake Shield, Removing and Installing"

2 - Wheel Bearing Housing

3 - Bracket

- For brake hose

4 - Bolt

- 20 Nm

5 - Bracket

- For brake hose

6 - Rivet

7 - Bracket

- For the brake line/hose

- On the body

8 - Spring

- Replace if damaged

9 - Brake Line

- Tightening specification, brake line to brake hose, 14 Nm

10 - Brake Hose

- Tightening specification: brake hose to brake caliper, 14 Nm

- Allocation. Refer to the Parts Catalog.

- Make sure the brake hose is routed correctly. Make sure the brake hose is not blocked, bent, twisted or rubbing against the vehicle.

- Replace if damaged

- Make sure that lugs are properly seated in grooves in bracket.

11 - Bolt

- 196 Nm

- Replace after removing

12 - Brake Pads

- Checking pad thickness. Refer to → for the wear limit.

- Always replace on both axles.

- Allocation. Refer to the Parts Catalog.

- Refer to → Chapter "Brake Pads, Removing and Installing"

- Installation position. Refer to → Fig. "Brake Pads Installation Position".

13 - Brake Pad Retaining Plate

- Replace when pads are replaced.

- Check for proper seating

14 - Brake Pad Spring

- Replace when pads are replaced.

- Check for proper seating

15 - Brake Pad Wear Indicator Wire

- With

- Left Front Brake Pad Wear Sensor -G34-

- Right Front Brake Pad Wear Sensor -G35-

- For inner brake pad

- Replace when replacing the brake pads.

- Refer to → Chapter "Brake Pad Wear Indicator Wire, Removing and Installing"

16 - Protective Cap

17 - Bleed Screw

- 10 Nm

- Before installing, thinly coat with Assembly Paste -G 052 150 A2-.

18 - Brake Caliper

- Allocation. Refer to the Parts Catalog.

- Do not loosen the brake caliper/brake carrier bolted connections. Refer to → Fig. "Do Not Loosen the Caliper/Brake Carrier Bolted Connections.".

- Refer to → Chapter "Brake Caliper, Removing and Installing"

- Refer to → Chapter "Brake Caliper, Replacing"

- Refer to → Chapter "Dust Cap, Removing and Installing"

19 - Brake Pad Retaining Plate

- Replace when pads are replaced.

- Check for proper seating

20 - Bolt

- 10 Nm

21 - Brake Rotor

- Allocation. Refer to the Parts Catalog.

- Always replace on both axles.

- Do not use excessive force to separate the brake rotors from the wheel hub. Use rust remover, if necessary, otherwise the brake rotors could be damaged.

- Refer to → Chapter "Brake Rotor, Removing and Installing"

22 - Bolt

- 10 Nm

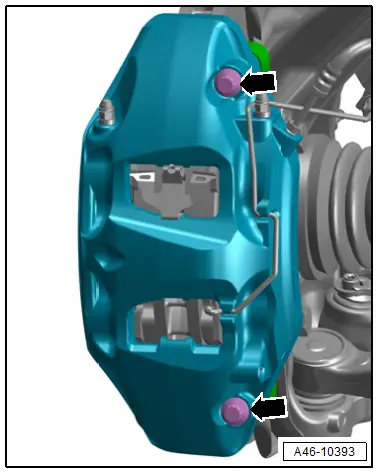

Do Not Loosen the Caliper/Brake Carrier Bolted Connections.

Caution

Caution

There is a risk of malfunctions.

Do not loosen the bolts -arrows- on the brake caliper.

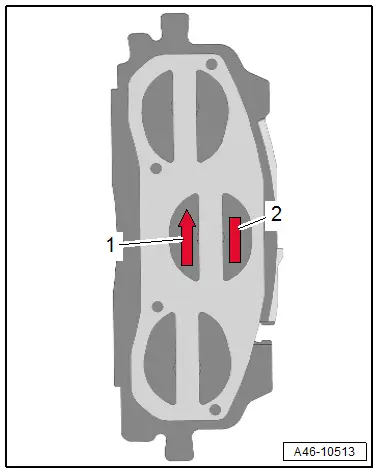

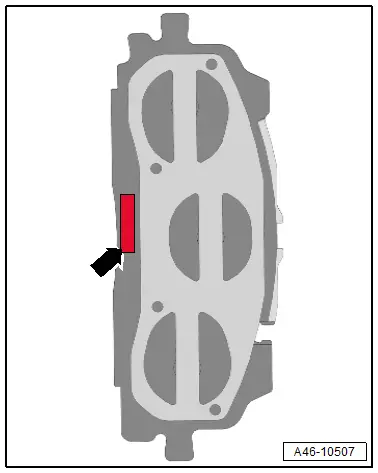

Brake Pads Installation Position

Version 1:

- Pay attention to the labeling -arrow- on the brake pads.

- LEFT OUTER

- LEFT INNER

- RIGHT OUTER

- RIGHT INNER

Version 2:

- Pay attention to the labeling -2- on the brake pads.

- LEFT OUTER

- LEFT INNER

- RIGHT OUTER

- RIGHT INNER

- In installed position, the arrow -1- on the backing plate of the brake pads must point upward.