Audi Q7: Seat Belts, Checking

WARNING

WARNING

After every accident the seat belt system must be inspected systematically! If damage is determined at any inspection point, the customer must be informed that it is necessary to replace the seat belt.

Inspection Points

- Check the seat belt webbing. Refer to → Chapter "Seat Belt Webbing, Checking".

- Check the automatic belt retractor (locking function). Refer to → Chapter "Automatic Belt Retractor (Locking Function), Checking".

- Visual inspection of the seat belt latch. Refer to → Chapter "Seat Belt Latch, Visually Inspecting".

- Seat belt latch function test. Refer to → Chapter "Seat Belt Latch, Function Test".

- Check the seat belt relays and belt tongue. Refer to → Chapter "Seat Belt Relays and Belt Tongue, Checking".

- Check the fasteners and mounting points. Refer to → Chapter "Fasteners and Mounting Points, Checking After a Collision".

- Check the function of the child seat anchorage for additional child seats (not for the driver safety belt). Refer to → Chapter "Seat Belt for Child Seat, Checking Child Seat Restraint Function, Market-Specific, Not for Driver Seat Belt".

Caution

Caution

If customer refuses to have a damaged seat belt replaced, appropriate Note should be made in the customer Maintenance booklet.

Seat Belt Webbing, Checking

Procedure

- Pull the belt completely out of the automatic belt retractor or lap belt adjustment tongue.

- Check the seat belt webbing for contamination, wash with mild soapy water if necessary. Refer to the Owner's Manual.

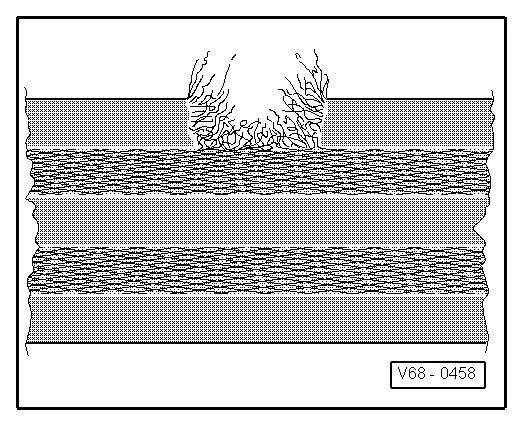

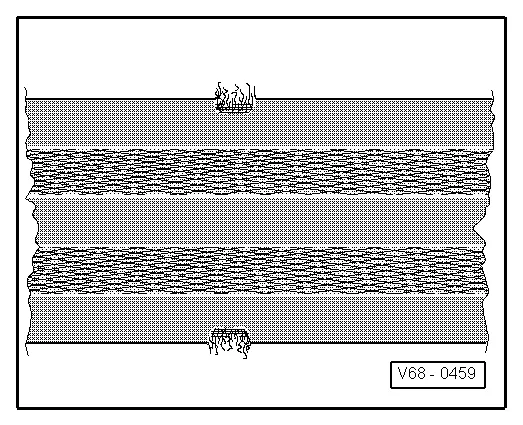

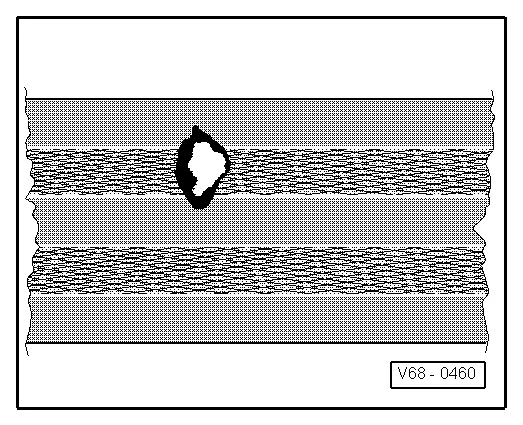

- If one of the types of damage (1 and 2) shown in the following is detected on a vehicle which has been in an accident - replace the entire seat belt with seat belt latch.

- If damage as illustrated under points 1, 2 or 3 is determined on a vehicle that has not been in an accident, only replace the damaged seat belt.

- 1 - Seat belt webbing cut, torn or frayed.

- 2 - Webbing loops on seat belt edge torn.

- 3 - Burn marks.

Automatic Belt Retractor (Locking Function), Checking

The automatic belt retractor has two locking functions.

- The first locking function is initiated by the belt being jerked out of the belt retractor (belt extraction acceleration).

Test 1

- Pull the seat belt webbing out of the automatic belt retractor with a firm jerk.

- No locking effect - replace the entire seat belt with seat belt latch.

- If difficulties are experienced when pulling out or retracting belt, first check whether position of the belt retractor has been altered.

- The second locking function is initiated by change in vehicle velocity (vehicle-dependent locking function).

Test 2

WARNING

WARNING

For safety reasons, road test should be carried out on traffic-free stretch to ensure that other motorists/pedestrians etc. are not endangered.

- Fasten the seat belt.

- Accelerate the vehicle to 20 km/h (12 mph) and then perform a hard braking maneuver with the foot brake.

- Replace the entire seat belt with the seat belt latch if the seat belt is not locked by locking mechanism during the braking procedure.

Seat Belt Latch, Visually Inspecting

- Inspect the seat belt latch for the formation of cracks and fracturing.

- If damaged, replace the entire seat belt with seat belt latch.

Seat Belt Latch, Function Test

Seat Belt Latch, Checking

- Insert the belt tongue into the seat belt latch until it clicks into place. Check whether the locking mechanism is properly engaged by giving the seat belt webbing a firm jerk.

- Replace the entire seat belt with the seat belt latch if the belt tongue fails even once to engage properly in the seat belt latch during at least five tests.

Release, Checking

- Press the seat belt latch with finger pressure to release the seat belt. With the seat belt webbing relaxed, the belt tongue must spring out of the seat belt latch without assistance.

- Perform the test at least five times. Replace the entire seat belt with the seat belt latch if the belt tongue fails to spring out even once.

WARNING

WARNING

Under no circumstances may lubricant be used to eliminate noise or stiffness at the seat belt latch buttons.

Seat Belt Relays and Belt Tongue, Checking

The plastic-covered guides show fine parallel grooves after straining of the belt system (belt was fastened during accident). (Wear from frequent belt use can be identified by smooth signs of wear that are free of scoring.)

- Check plastic for deformation, rupture and the formation of cracks.

- For groove build-up and/or damage, replace the entire seat belt with the seat belt latch.

Fasteners and Mounting Points, Checking After a Collision

- Seat belt latch tongue deformed (fully extended).

- Height adjustment not functional.

- Anchorage points (seat, pillar, vehicle floor) distorted or threads damaged.

- If damage is found on the components, replace the entire seat belt with the seat belt latch.

- If parts of the seat belt system are removed due to an accident, replace the belt system bolts.

- Replace the mounting points.

Note

Note

In damage is discovered that is not accident-related, for example, wear, replace only the particular part which is damaged.

Seat Belt for Child Seat, Checking Child Seat Restraint Function, Market-Specific, Not for Driver Seat Belt

To check the function, the entire belt system must be installed, including the side trim panel.

Hold Function, Switching On

- Pull out the seat belt all the way.

Proper Function

- The belt must retract with a chattering sound.

- If the retracting process is stopped, the belt cannot be pulled out anymore.

Switching Off

- Belt retraction to about 100 mm remaining.

- Hold function must switch off with a remainder of 100 mm, at the latest. The belt functions normally again.

If the seat belt child seat anchorage does not work, replace the seat belt.

Child Seat Anchors, Checking After Collision

Inspection Points

- Child seat anchors must be checked for damage or deformation after a collision.

- Child seat anchors welded or bolted into the body or the seat or backrest must not be repaired or straightened.

- Child seat anchors bolted into the body, seat or backrest must be replaced if damaged or deformed.

- Child seat anchors securing bolts should be replaced if bracket is damaged.

Automatic Dimming Interior Rearview Mirror Safety Precautions

WARNING

WARNING

- To produce its unique properties, the interior rearview mirror glass is composed of several layers and contains an electrolyte. Be careful of electrolyte leaking from a broken mirror.

- The liquid electrolyte can cause irritation to the skin, eyes and respiratory system.

- If liquid electrolyte comes into contact with the eyes or skin, flush thoroughly with plenty of water. If irritation persists, seek medical attention immediately.

Caution

Caution

Electrolyte leaking from a broken mirror will damage all plastic surfaces it comes in contact with. Remove spilled electrolyte immediately using clean water and a sponge.

Repair Information

Contact Corrosion

Contact corrosion can occur if incorrect fasteners (bolts, nuts, washers, etc.) are used.

For this reason, only fasteners with a special surface coating are installed.

In addition, rubber or plastic parts and adhesives consist of non-conductive materials.

If there are doubts as to whether parts can be reused or not, use new parts. Refer to the Parts Catalog.

Note

Note

- The use of original replacement parts is recommended, since they are tested and are compatible with aluminum.

- The use of Audi accessories is recommended.

- Contact corrosion damage is not covered under warranty!

Line Routing and Securing

When loosening or removing and installing hydraulic, pneumatic lines or wires, draw sketches or take pictures. This ensures installation is the same as the original.