Audi Q7: Supercharger

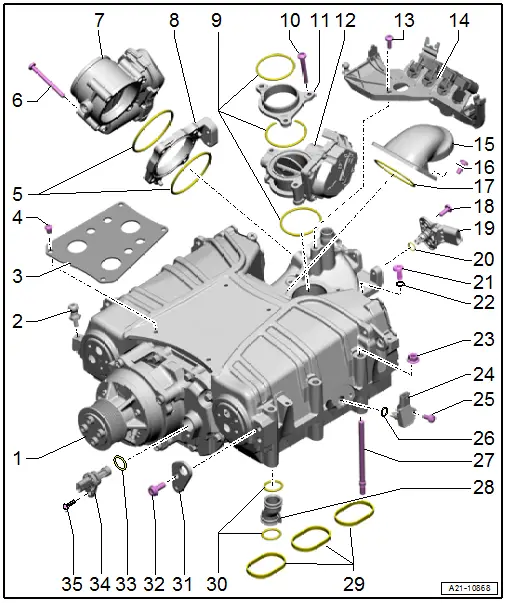

Overview - Supercharger

1 - Supercharger

- With charge air coolers

- Supercharger, Removing and installing. Refer to → Chapter "Supercharger, Removing and Installing".

- Overview - Charge Air Cooler. Refer to → Chapter "Overview - Charge Air System".

- Secured on the Engine and Gearbox Bracket -VAS6095A- for repair work. Refer to → Chapter "Supercharger, Securing to Engine/Transmission Holder for Repair Work".

- Secured on the Engine and Gearbox Bracket -VAS6095A- for leak test. Refer to → Chapter "Supercharger, Securing to Engine/Transmission Holder for Leak Test".

2 - Ball Pin

- 5 Nm

- For the engine cover

3 - Insulation Plate

4 - Bolt

- 5 Nm

5 - O-Rings

- Replace after removing

6 - Bolt

- Tightening specification. Refer to → Fig. " Throttle Valve Control Module -J338- - Tightening Specification".

7 - Throttle Valve Control Module -J338-

- Removing and installing. Refer to → Chapter "Throttle Valve Control Module -J338-, Removing and Installing".

8 - Intermediate Flange

9 - O-Rings

- Replace after removing

10 - Bolt

- Tightening specification and sequence. Refer to → Fig. " Regulating Flap Control Unit -J808- - Tightening Specification and Sequence".

11 - Intermediate Flange

12 - Regulating Flap Control Unit -J808-

- Removing and installing. Refer to → Chapter "Regulating Flap Control Unit -J808-, Removing and Installing".

13 - Bolt

- 9 Nm

14 - Bracket

- For change-over valves

15 - Connection

16 - Bolt

- Tightening specification and sequence. Refer to → Fig. " Regulating Flap Control Unit -J808- - Tightening Specification and Sequence".

17 - O-Ring

- Replace after removing

18 - Bolt

- 10 Nm

19 - Intake Air Temperature Sensor -G42-/ Manifold Absolute Pressure Sensor -G71-

- Removing and installing. Refer to → Chapter "Intake Air Temperature Sensor -G42-/Manifold Absolute Pressure Sensor -G71-, Removing and Installing".

20 - O-Ring

- Replace after removing

21 - Bleed Screw

- 1.5 to 3.0 Nm

- For the charge air cooler

22 - Gasket

- Replace after removing

23 - Nut

- 20 Nm

24 - Charge Air Pressure Sensor/Charge Air Pressure Sensor

- Cylinder bank 1 (right) Charge Air Pressure Sensor -G31-/Intake Manifold Temperature Sensor -G72-

- Cylinder bank 2 (left) Charge Air Pressure Sensor 2 -G447-/Intake Manifold Temperature Sensor 2 -G430-

- Removing and installing. Refer to → Chapter "Charge Air Pressure Sensor/Intake Manifold Temperature Sensor, Removing and Installing".

25 - Bolt

- 10 Nm

26 - O-Ring

- Replace after removing

27 - Stud Bolt

- 17 Nm

28 - Connection

- For the crankcase ventilation

- Installation position. Refer to → Fig. "Crankcase Ventilation Connection, Installing".

29 - Seals

- Replace after removing

30 - O-Rings

- Replace after removing

- Quantity 2 each

31 - Engine Lifting Eye

32 - Bolt

- 27 Nm

33 - O-Ring

- Replace after removing

34 - Turbocharger Speed Sensor 1 -G688-

- Removing and installing. Refer to → Chapter "Turbocharger Speed Sensor 1 -G688-, Removing and Installing".

- The opening cannot be used as an oil level display

35 - Bolt

- 10 Nm

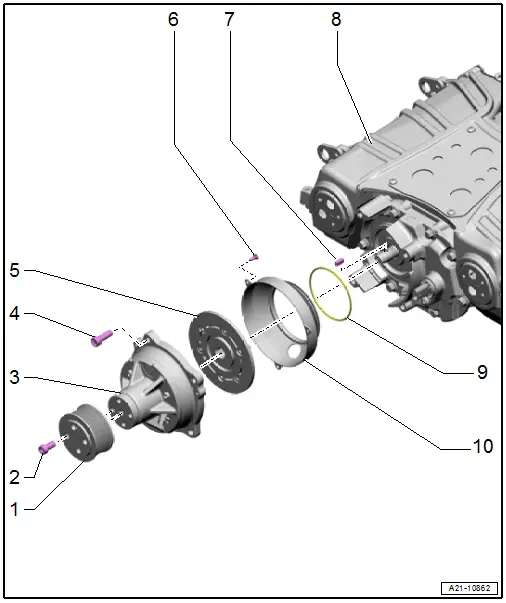

Overview - Solenoid Coupling

1 - Belt Pulley

- For the supercharger

- Removing and installing. Refer to → Chapter "Supercharger Belt Pulley, Removing and Installing".

2 - Bolt

- 20 Nm +90º

- Replace after removing

3 - Solenoid Coupling

- Removing and installing. Refer to → Chapter "Solenoid Coupling, Removing and Installing".

4 - Bolt

- 20 Nm

5 - Driver

- Tightening specification for the clamping screw. Refer to → Fig. "Tightening Specification for the Clamping Screw"

- Replace only together with -3-

- Do not loosen the threaded connections on the drive plate

- Replace the drive plate if the threaded connections are loosened

- Removing and installing. Refer to → Chapter "Solenoid Coupling, Removing and Installing".

- Clean the friction lining and friction surface before installing with brake cleaner

6 - Bolt

- 3.6 Nm

7 - Woodruff Key

8 - Supercharger

9 - O-Ring

- Replace after removing

10 - Trim

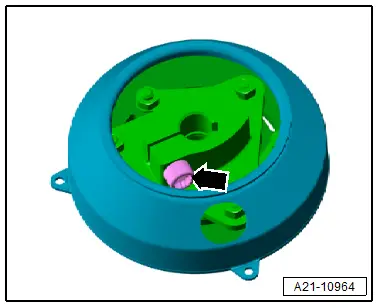

Tightening Specification for the Clamping Screw

- Tighten the clamping screw -arrow- to 20 Nm.

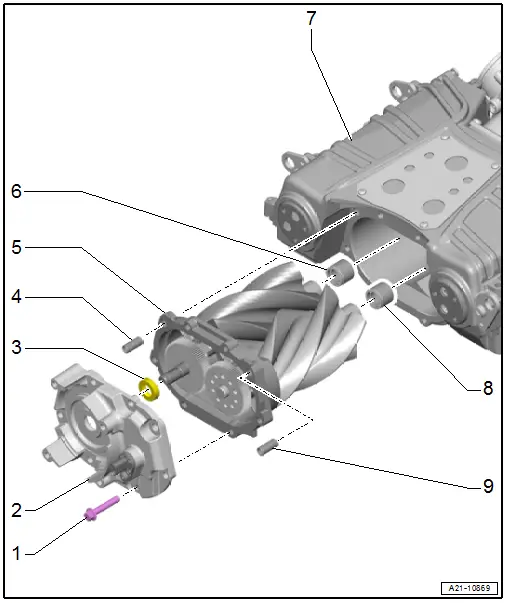

Overview - Rotor Unit

1 - Bolt

- 27 Nm

- Remove the old seal or locking fluid from the threads (for example with a thread tap)

- Before installing coat a few threads of the cleaned bolts with locking fluid. Refer to the Parts Catalog.

2 - Drive Head

- Replace the seal -3-, after every removal

- Removing and installing. Refer to → Chapter "Operating Head, Removing and Installing".

3 - Seal

- For the input shaft

- Replacing. Refer to → Chapter "Input Shaft Seal, Replacing".

4 - Alignment Sleeve

5 - Rotor Unit

- Removing and installing. Refer to → Chapter "Rotor Unit, Removing and Installing".

- After every removal and installation. Refer to → Chapter "Supercharger, Checking for Leaks".

- Remove the old seal or locking fluid from the threaded holes (for example with a thread tap)

6 - Needle Bearing

- For the rotor unit

- Replace together with the rotor unit. Refer to → Chapter "Rotor Unit, Removing and Installing".

7 - Supercharger Housing

8 - Needle Bearing

- For the rotor unit

- Replace together with the rotor unit. Refer to → Chapter "Rotor Unit, Removing and Installing".

9 - Alignment Sleeve