Audi Q7: Supercharger Belt Pulley, Removing and Installing

Special tools and workshop equipment required

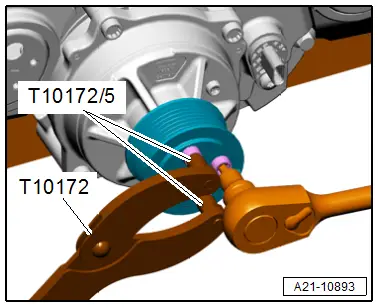

- Counterhold - Multiple Use -T10172A- with Counterhold - Kit - Adapter 5 -T10172/5-

Caution

Caution

This procedure contains mandatory replaceable parts. Refer to component overview prior to starting procedure.

Mandatory Replacement Parts

- Bolts -Supercharger belt pulley

Removing

- Remove the engine cover. Refer to → Chapter "Engine Cover, Removing and Installing".

- Remove the supercharger ribbed belt. Refer to → Chapter "Ribbed Belt, Removing and Installing, Supercharger Ribbed Belt".

- Loosen the two belt pulley bolts a turn, while doing so counter hold on the other two bolts with the Counterhold - Kit - Multiple Use -T10172A- and Counterhold - Kit - Adapter 5 -T10172/5-.

- Place the counterholder on the loosened bolts and remove the two other bolts.

- Remove the remaining bolts and the belt pulley.

Installing

Note

Note

Replace supercharger belt pulley bolts after removal.

Install in reverse order of removal and note the following:

- Install the supercharger ribbed belt. Refer to → Chapter "Ribbed Belt, Removing and Installing, Supercharger Ribbed Belt".

- Install the engine cover. Refer to → Chapter "Engine Cover, Removing and Installing".

Tightening Specifications

- Refer to → Chapter "Overview - Solenoid Coupling"

Operating Head, Removing and Installing

Special tools and workshop equipment required

- Used Oil Collection and Extraction Unit -SMN372500-

- Assembly Sleeve -T40318-, not illustrated

- Sealant. Refer to the Parts Catalog.

- Oil for the supercharger drive. Refer to the Parts Catalog.

- Expanding pliers (commercially available)

Removing

- Supercharger secured to engine/transmission holder for repair work. Refer to → Chapter "Supercharger, Securing to Engine/Transmission Holder for Repair Work".

- Remove the solenoid coupling. Refer to → Chapter "Solenoid Coupling, Removing and Installing".

- Hold the supercharger perpendicular on the engine/transmission holder.

- The drive head faces up.

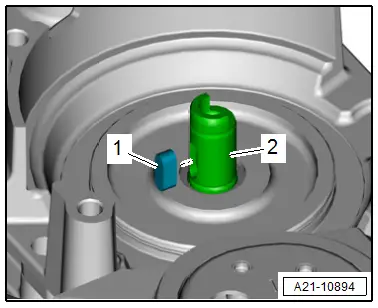

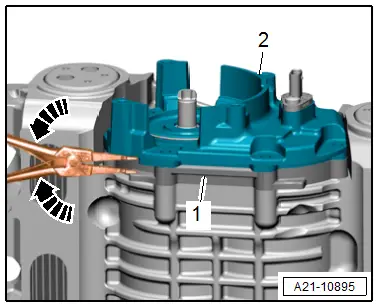

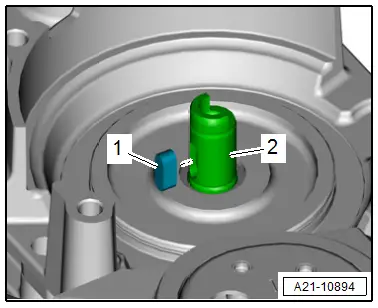

- Remove the woodruff key -1- from drive axle -2-.

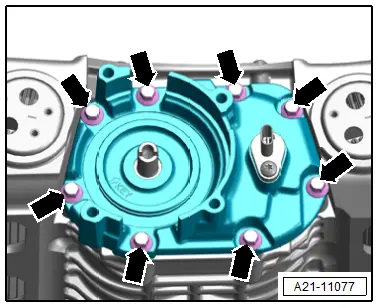

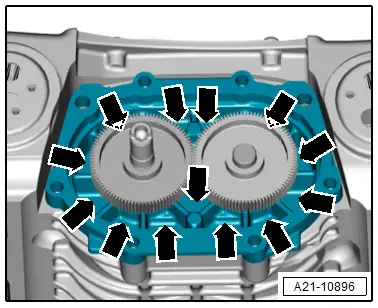

- Remove the bolts -arrows-.

Caution

Caution

To prevent the rotor unit bearing cap -1- from coming and loose and having to be sealed again, do not use a hammer to remove the drive head -2- but rather use expanding pliers in direction of -arrows-, as illustrated.

- Carefully remove the operating head with expanding pliers from the bearing cap.

- Extract all the oil for the supercharger drive from the bearing cap as well as from the oil pockets -arrows- between the ribs using the Used Oil Collection and Extraction Unit -SMN372500-.

Installing

Note

Note

- Replace the operating head gaskets after disassembly.

- Insert the self-locking bolts or bolts with sealant. Refer to the Parts Catalog.

- Clean any oil or grease off the sealing surfaces.

- Always clean the threaded holes with a thread tap before assembling.

- Fill the oil for the supercharger drive in the bearing cap.

Note

Note

The container holds the exact amount. It is not necessary to check the oil level later.

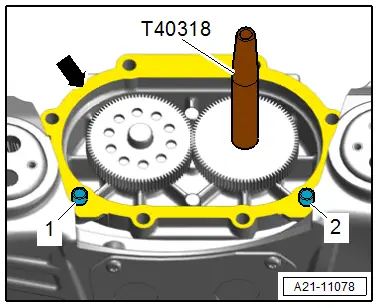

- Apply sealant thinly on the sealing surface -arrow- for the operating head on the rotor unit and place the Assembly Sleeve -T40318- on the drive axle as shown.

- Place the operating head with a new seal on the rotor unit, at the same time pay attention to the alignment sleeves -1 and 2-.

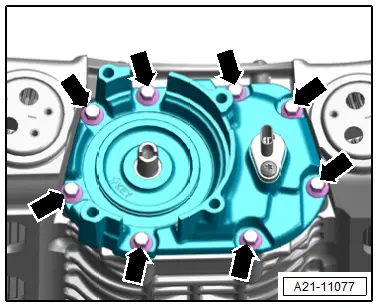

- Tighten the bolts -arrows-.

- Insert the woodruff key -1- in the drive axle -2-.

- Install the solenoid coupling. Refer to → Chapter "Solenoid Coupling, Removing and Installing".

Installation is performed in reverse order of removal, while noting the following:

- Check the supercharger for leaks. Refer to → Chapter "Supercharger, Checking for Leaks".

Tightening Specifications

- Refer to → Chapter "Overview - Rotor Unit"

Rotor Unit, Removing and Installing

Special tools and workshop equipment required

- Internal Puller -VAS501001-, not illustrated

- Thrust Piece -T40303-

Caution

Caution

This procedure contains mandatory replaceable parts. Refer to component overview prior to starting procedure.

Mandatory Replacement Parts

- Needle Bearings - Rotor unit

Removing

- Supercharger secured to engine/transmission holder for repair work. Refer to → Chapter "Supercharger, Securing to Engine/Transmission Holder for Repair Work".

- Remove the solenoid coupling. Refer to → Chapter "Solenoid Coupling, Removing and Installing".

- Remove the operating head. Refer to → Chapter "Operating Head, Removing and Installing".

- Hold the supercharger perpendicular on the engine/transmission holder.

- The rotor unit spur gears point upward.

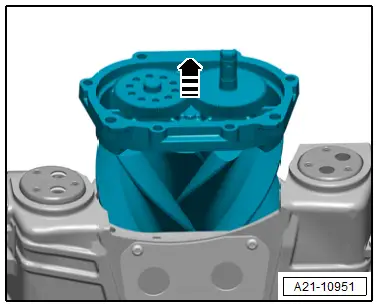

- Carefully remove the rotor unit upward in direction of -arrow- while doing so pay attention that the compressor housing rotors inner surfaces are not damaged.

- Place the rotor unit carefully aside and protect from dust.

- To prevent dirt and small parts from entering into the compressor housing, seal the air duct with clean cloths.

Caution

Caution

There is a risk of damaging the compressor housing surfaces.

If required for the following steps protect the surfaces on the compressor housing with cloths.

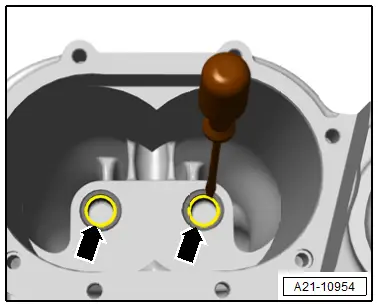

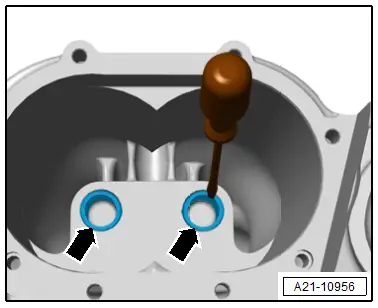

- Bend the seals -arrows- for the rotors needle bearing on both mounts toward the inside with a screwdriver.

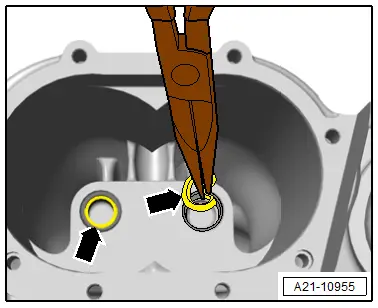

- Remove the seals -arrows- for the rotors needle bearing on both mounts with needle nose pliers.

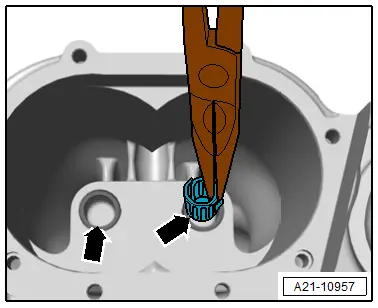

- Break off the needle bearing cages -arrows- on both mounts with a screwdriver.

- Remove the needle bearing cages -arrows- from both mounts with needle nose pliers.

- Completely remove the loose mount rolls with a magnet.

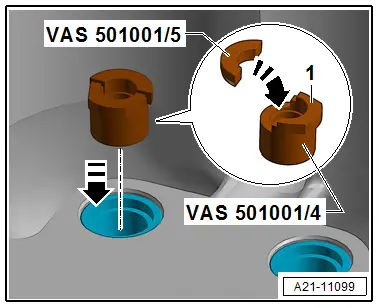

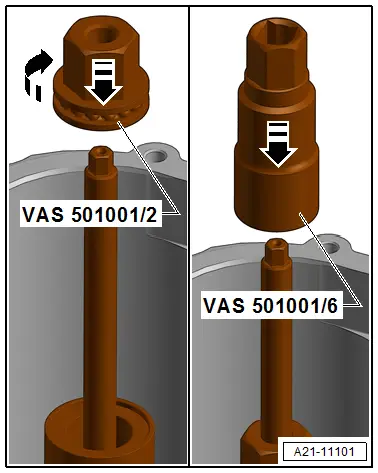

- Insert the Threaded Bushing - VAS501001/4- in the needle bearing sleeve, make sure that the collar -1- points upward.

- Place the Thrust Plate -VAS501001/5- on the Threaded Bushing - VAS501001/4- the tool labeling points upward.

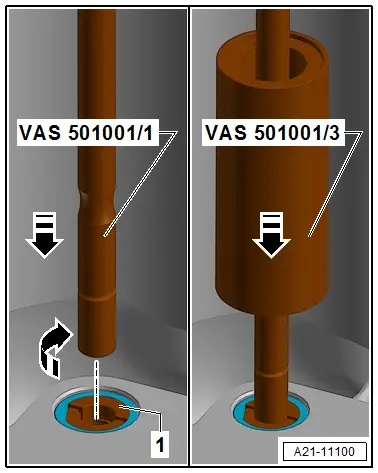

- Install the Spindle - VAS501001/1- all the way hand-tight in the Threaded Bushing -VAS501001/4--1-.

- Position the Press Sleeve -VAS501001/3- the end with the flat front side faces downward.

- Install the Thrust Nut -VAS501001/2- on the spindle.

- Place the Internal Puller - Socket -VAS501001/6- on the thrust nut.

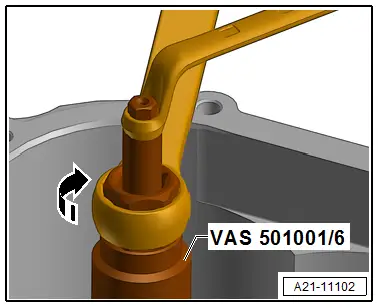

- Remove the needle bearing sleeve by turning the Internal Puller - Socket -VAS501001/6-. At the same time, use a suitable tool to counterhold at the Internal Puller - Spindle -VAS501001/1-.

- Remove the sleeve from the second needle bearing in the same way.

Installing

- Always clean the bearing seats and bolting surfaces for the rotor unit.

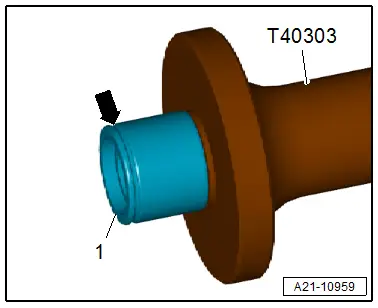

- Place the new needle bearing on the Thrust Piece - T40303-.

- The groove -arrow- points to the compressor housing.

- The seal in the needle bearing points to the tool.

Caution

Caution

There is a risk of thinning the grease in the needle bearing from applying too much engine oil.

Only apply engine oil very thinly.

- Coat the outer edge (sleeve) of the needle bearing with engine oil.

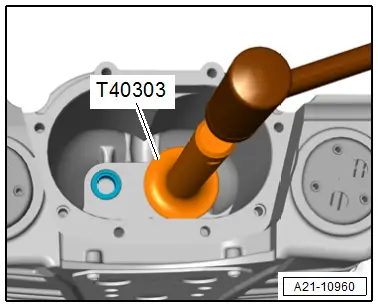

- Place the needle bearing with the Thrust Piece -T40303- straight in the compressor housing hole and drive in all the way with a large plastic mallet.

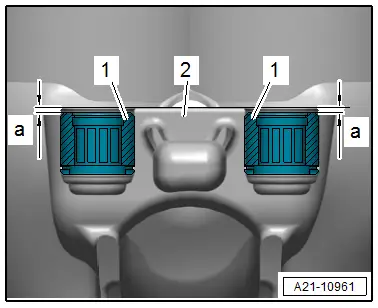

- After driving in the needle bearing -1- check its seating in the compressor housing -2-.

- Dimension -a- = 1.5 mm

- If required drive in the needle bearing further.

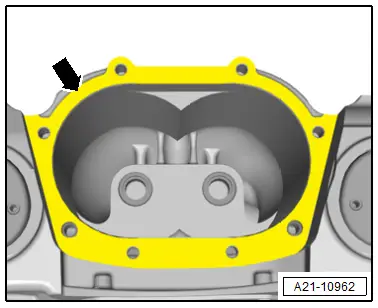

- Apply a thin coat of sealant -arrow- on the rotor unit sealing surface for the compressor housing.

- Carefully insert the rotor unit in the compressor housing.

- Pay attention that the supercharger housing rotors inner surfaces are not damaged and that the rotor axles are guided into the needle bearing.

- Install the operating head. Refer to → Chapter "Operating Head, Removing and Installing".

- Install the solenoid coupling. Refer to → Chapter "Solenoid Coupling, Removing and Installing".

- Check the supercharger for leaks. Refer to → Chapter "Supercharger, Checking for Leaks".

Input Shaft Seal, Replacing

Special tools and workshop equipment required

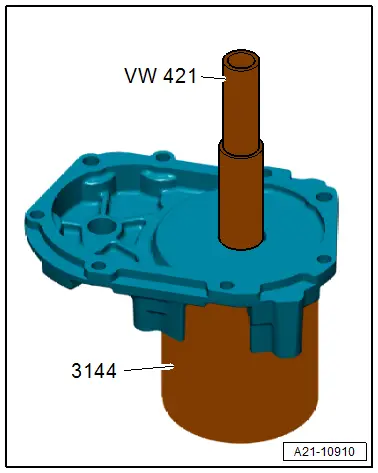

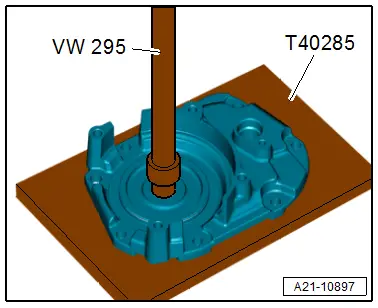

- Bearing/Bushing Installer - Multiple Use -VW295-

- Bearing Installer - Wheel Bearing -3144-

- Plate -T40285-

Caution

Caution

This procedure contains mandatory replaceable parts. Refer to component overview prior to starting procedure.

Mandatory Replacement Parts

- Seal - Input shaft

Procedure

- Remove the operating head. Refer to → Chapter "Operating Head, Removing and Installing".

- Place the operating head with the front side upward on the Plate -T40285- as shown in the illustration.

- Drive out the seal from the operating head using the Bearing/Bushing Installer - Multiple Use -VW295- .

- Place the operating head with the front side downward on the workbench.

- Drive in the gasket with the Bearing Installer - Wheel Bearing -3144-.

- Installation position: the open side of the gasket points to the tool.

- Install the operating head. Refer to → Chapter "Operating Head, Removing and Installing".