Audi Q7: Charge Air System

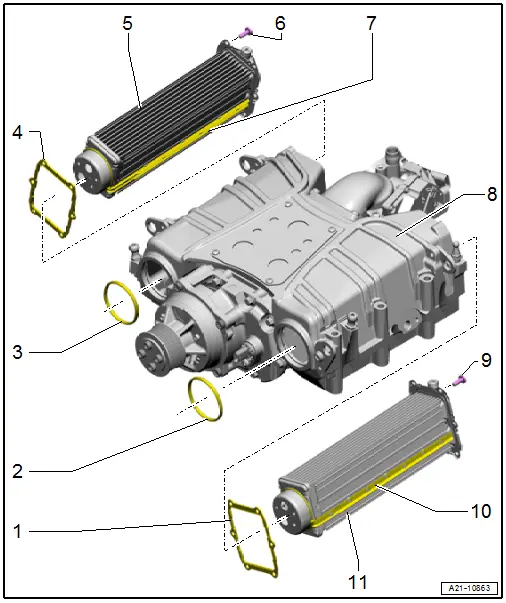

Overview - Charge Air System

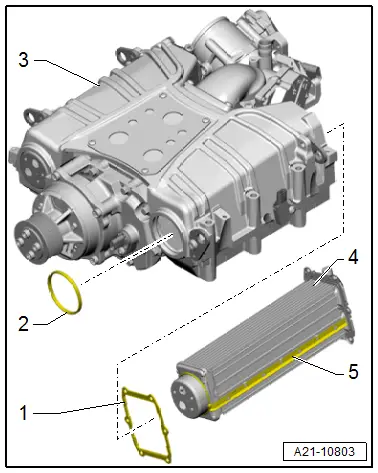

1 - Seal

- Replace after removing

2 - O-Ring

- Replace after removing

- Coat with engine oil when installing the charge air cooler

3 - O-Ring

- Replace after removing

- Coat with engine oil when installing the charge air cooler

4 - Seal

- Replace after removing

5 - Right Charge Air Cooler

- Removing and installing. Refer to → Chapter "Charge Air Cooler, Removing and Installing".

6 - Bolt

- 10 Nm

- Replace after removing

- Self-locking

7 - Seal

- Not available separately.

- May not be removed from the charge air cooler

- Coat with engine oil when installing the charge air cooler

8 - Supercharger Housing

9 - Bolt

- 10 Nm

- Replace after removing

- Self-locking

10 - Seal

- Not available separately.

- May not be removed from the charge air cooler

- Coat with engine oil when installing the charge air cooler

11 - Left Charge Air Cooler

- Removing and installing. Refer to → Chapter "Charge Air Cooler, Removing and Installing".

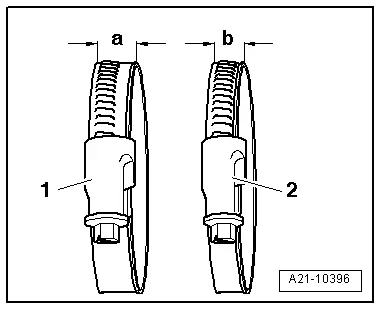

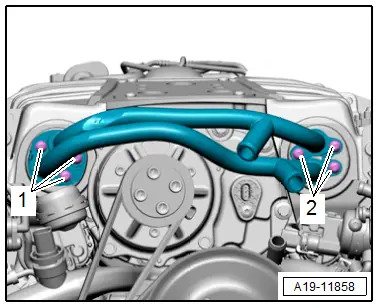

Overview - Charge Air Hose Connections

Note

Note

- The hose connections as well as air duct pipes and hoses must be free of oil and grease before installing.

- Secure all hose connections with hose clamps that match the ones used in series production. Refer to the Parts Catalog.

- In order to be able to securely mount the air duct hoses on their connections, spray the bolts on the previously used screw-type clamps with rust remover before installing.

Tightening specification for

1 - Hose clamp -a- = 13 mm wide: 5.5 Nm

2 - Hose clamp -b- = 9 mm wide: 3.4 Nm

Charge Air Cooler, Removing and Installing

Special tools and workshop equipment required

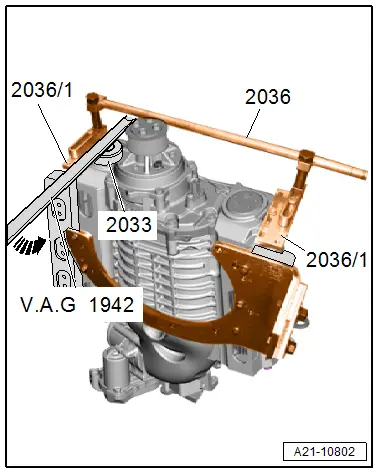

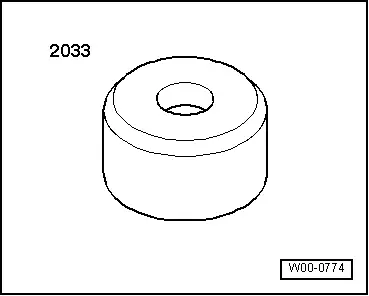

- Arbor -2033-

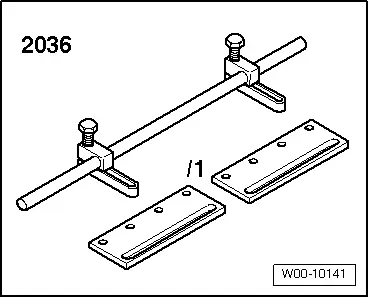

- Seal Installer - Valve Stem Seal Tool -2036-

- Tire pry lever, commercially available or the Pry Lever -VAG1942-

Caution

Caution

This procedure contains mandatory replaceable parts. Refer to component overview prior to starting procedure.

Mandatory Replacement Parts

- Bolts - Charged air coolers

- O-rings - Charged air coolers

- Seals - Charged air coolers

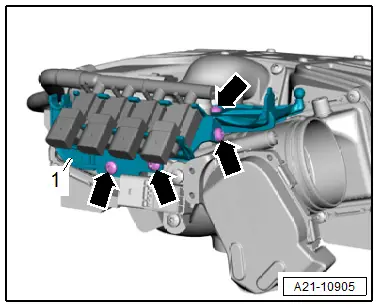

Removing

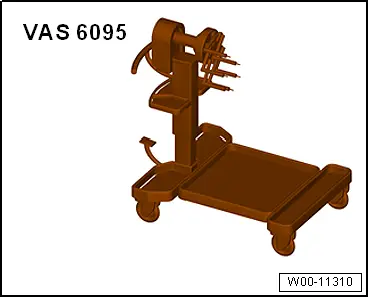

- Supercharger secured on the Engine and Gearbox Bracket -VAS6095A- for repair work. Refer to → Chapter "Supercharger, Securing to Engine/Transmission Holder for Repair Work".

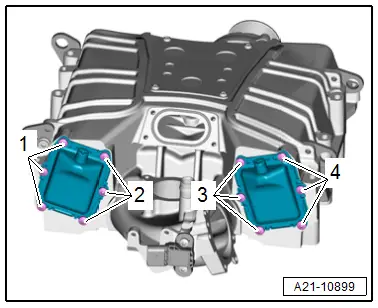

- Remove the bolts -arrows-, and remove the bracket -1- with the bypass valves.

Left Charge Air Cooler:

- Remove the charge air pressure sensor/intake manifold temperature sensor. Refer to → Chapter "Charge Air Pressure Sensor/Intake Manifold Temperature Sensor, Removing and Installing".

Right Charge Air Cooler:

- Remove the Throttle Valve Control Module -J338-. Refer to → Chapter "Throttle Valve Control Module -J338-, Removing and Installing".

- Remove the charge air pressure sensor/intake manifold temperature sensor. Refer to → Chapter "Charge Air Pressure Sensor/Intake Manifold Temperature Sensor, Removing and Installing".

Continuation for Both Sides:

- Remove the bolts -1 and 2- and the coolant pipes from the compressor.

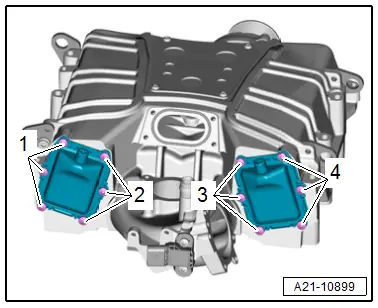

- Remove the charge air cooler bolts on the left -1 and 2- and right -3 and 4-.

- Attach the Seal Installer - Valve Stem Seal Tool -2036- with the Seal Installer - Valve Stem Seal Tool Adapter Plates -2036/1- to the supercharger as illustrated.

- Position the Arbor -2033- on the front of the charge air cooler.

- Slowly remove the charge air cooler with even pressure from the supercharger housing using the Tire Pry Lever -VAG1942-.

Installing

Note

Note

- Replace the seals, O-rings and self-locking screws after removing.

- Always clean the threaded holes inside the supercharger housing with a thread tap before assembling.

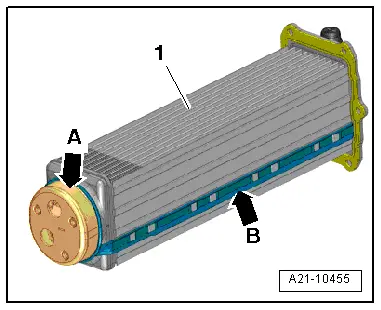

- Check the seal -5- on the charge air cooler -4-.

- The seal must not be cracked or damaged.

- Slide the seal -1- onto the charge air cooler.

- Insert the O-ring -2- into the opening in the supercharger housing -3-.

- Coat the sealing surface -arrow A- and the charge air cooler seal -arrow B--1- with engine oil.

- Coat the inner sealing surface inside the supercharger housing with engine oil.

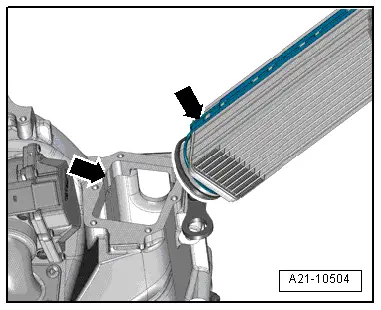

- Make sure the seals are opposite the openings in the supercharger housing when installing the charge air cooler -arrows-.

Note

Note

Holding the supercharger housing perpendicular in the Engine and Gearbox Bracket -VAS6095A- makes it easier to install and remove the charge air cooler.

Caution

Caution

Danger of causing damage to the charge air cooler.

Install the charge air cooler by hand only.

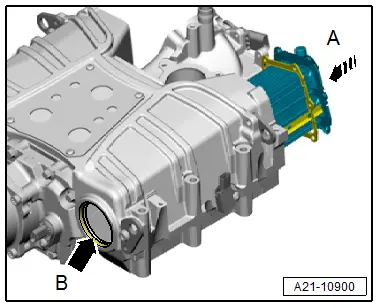

- Install the charge air cooler all the way into the supercharger housing by hand in direction of -arrow A-. When doing this, let the front of the charge air cooler slide into the hole -arrow B- inside the supercharger housing.

- Manually guide the charge air cooler by hand through the supercharger housing openings -arrows-, if necessary.

- As soon as it is possible, install the two bolts loosely by hand to help guide the charge air cooler.

Caution

Caution

Danger of causing damage to the charge air cooler.

- The charge air cooler may not be installed by using the bolts.

- Install the charge air cooler by hand only until there is maximum 1 mm between the sealing flange and the seal and the supercharger housing. Only then should the bolts be tightened as follows:

- Tighten the bolts for the left -1 and 2- and right -3 and 4- charge air coolers in a diagonal sequence and in small steps.

Installation is performed in reverse order of removal, while noting the following:

- Install the coolant pipes to the supercharger. Refer to → Chapter "Supercharger Coolant Pipes, Removing and Installing".

- Install the Throttle Valve Control Module -J338-. Refer to → Chapter "Throttle Valve Control Module -J338-, Removing and Installing".

- Install the charge air pressure sensor/intake manifold temperature sensor. Refer to → Chapter "Charge Air Pressure Sensor/Intake Manifold Temperature Sensor, Removing and Installing".

- Check the supercharger for leaks. Refer to → Chapter "Supercharger, Checking for Leaks".

Tightening Specifications

- Refer to → Chapter "Overview - Charge Air System"

Charge Air Pressure Sensor/Intake Manifold Temperature Sensor, Removing and Installing

Caution

Caution

This procedure contains mandatory replaceable parts. Refer to component overview prior to starting procedure.

Mandatory Replacement Parts

- O-ring - Charge Air Pressure Sensor/Intake Manifold Temperature Sensor

Removing

- Remove the supercharger. Refer to → Chapter "Supercharger, Removing and Installing".

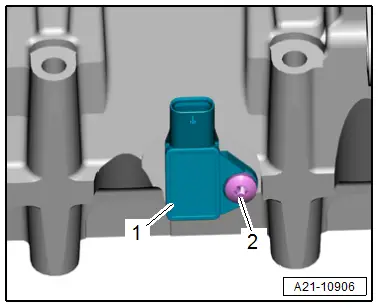

- Remove the bolt -2- and remove the charge air pressure sensor/intake manifold temperature sensor -1-.

Installing

Install in reverse order of removal and note the following:

Note

Note

- Replace the self-locking screws and O-ring after removal.

- Clean the threaded holes for the charge air pressure sensor inside the supercharger housing with a thread tap before assembling.

- Install the supercharger. Refer to → Chapter "Supercharger, Removing and Installing".

Tightening Specifications

- Refer to → Chapter "Overview - Supercharger"

Special Tools

Special tools and workshop equipment required

- Used Oil Collection and Extraction Unit -SMN372500-

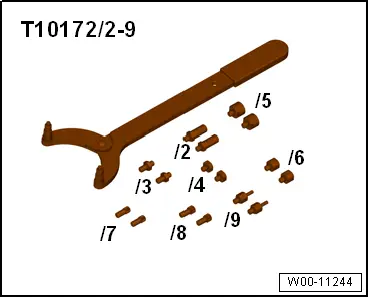

- Counterhold - Multiple Use -T10172A- with Counterhold - Kit - Adapter 5 -T10172/5-

- Gearbox Support -T40206- with -T40206/1-

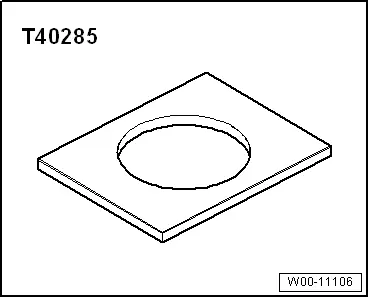

- Plate -T40285-

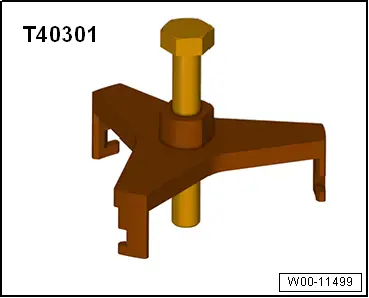

- Clutch Module Puller -T40301-

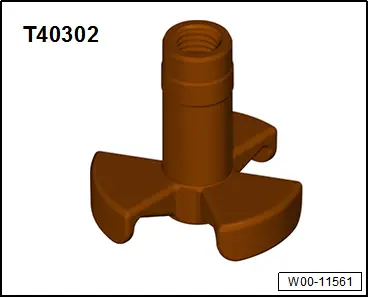

- Clutch Module Centering Device -T40302-

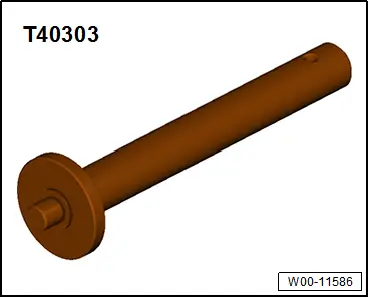

- Thrust Piece -T40303-

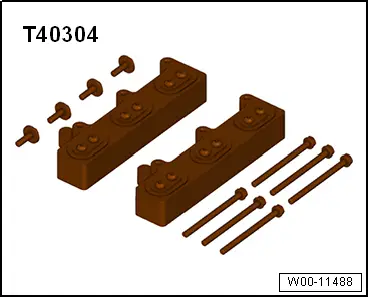

- Supercharger Module Support -T40304-

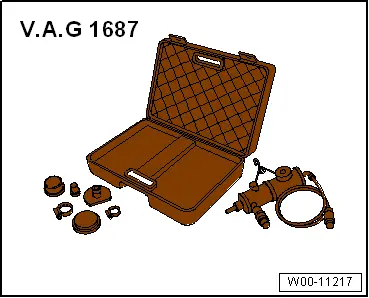

- Turbo System Tester Kit Adapter - VAG1687/4-, T urbo System Tester Kit - Adapter 10 -VAG1687/10-, Turbo System Tester Kit - Adapter 13-1 -VAG1687/13-1- and Turbo System Tester Kit - Adapter 13-2 -VAG1687/13-2-

- Engine and Gearbox Bracket -VAS6095A-

- Engine Bung Set -VAS6122-

- Container of the Coolant Collection System -VAS5014- or the Shop Crane - Drip Tray -VAS6208-

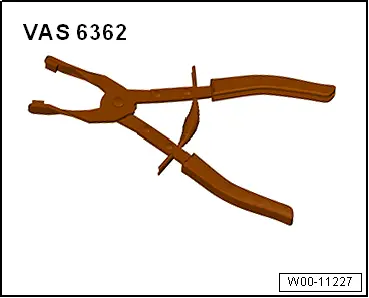

- Hose Clip Pliers -VAS6362-

- Bearing/Bushing Installer - Multiple Use -VW295-

- Arbor -2033-

- Seal Installer - Valve Stem Seal Tool -2036-

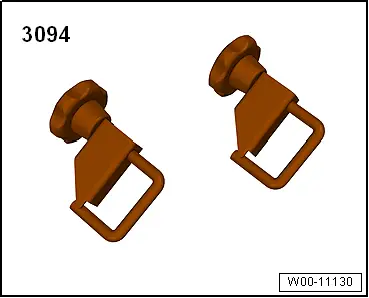

- Hose Clamps - Up To 25mm -3094-

- Bearing Installer - Wheel Bearing -3144-

- Turbo System Tester Kit -VAG1687-

- Test Adapter For Compressor Module -VAS6909A-

- Internal Puller -VAS501001-

- Tire pry lever, commercially available or the -VAG1942-