Audi Q7: ATF

ATF Level, Checking

ATF Level, Checking, 0D3 "Sport Differential"

Caution

Caution

This procedure contains mandatory replaceable parts. Refer to component overview prior to starting procedure.

Mandatory Replacement Parts

- Plug - ATF check

Test Requirement

- ATF temperature: 10 ºC to 60 ºC (50 to 140 ºF)

- The rear final drive must be in the installed position.

- The vehicle must be level.

- Refer to → Chapter "Component Location Overview - Drain and Check Plugs, 0D3 Sport Differential"

Special tools and workshop equipment required

- Drip Tray

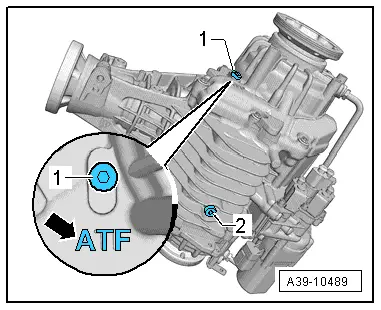

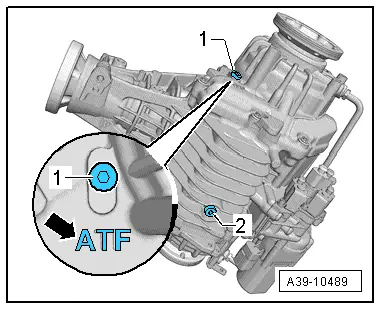

- Remove the ATF check plug -1- to check the ATF level.

Tip:

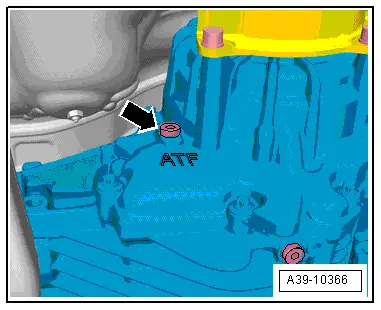

- The ATF check plug -1- is located on the left side of the rear final drive. Identification "ATF" on the final drive housing -arrow-

- ATF plug overview. Refer to → Chapter "Component Location Overview - Drain and Check Plugs, 0D3 Sport Differential".

- The ATF level is correct when the rear final drive is filled to the lower edge of the fill hole.

If the ATF is correct:

- Install the new ATF check plug and fasten. Tightening specification. Refer to → Fig. "ATF Drain Plugs on Rear Final Drive 0D3".

If the ATF is not correct:

- Fill the ATF. Refer to → Chapter "ATF, Filling, 0D3 Sport Differential".

ATF, Draining and Filling

ATF, Draining, 0D3 "Sport Differential"

Special tools and workshop equipment required

- Drip Tray

Caution

Caution

This procedure contains mandatory replaceable parts. Refer to component overview prior to starting procedure.

Mandatory Replacement Parts

- Plug - ATF drain

- Plug - ATF check

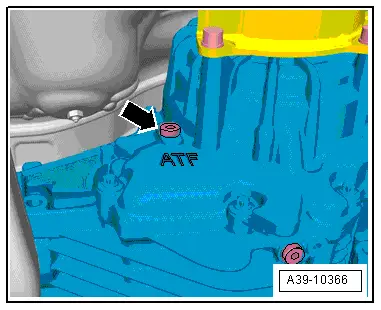

- Remove the ATF check plug -arrow- so that the ATF drains faster.

- Remove the ATF drain plug -arrow- and drain the ATF.

- Install the new ATF drain plug -arrow- and tighten. Tightening specification. Refer to → Fig. "ATF Drain Plugs on Rear Final Drive 0D3".

- Fill the ATF in the rear final drive. Refer to → Chapter "ATF, Filling, 0D3 Sport Differential".

ATF, Filling, 0D3 "Sport Differential"

Special tools and workshop equipment required

- Vehicle Diagnostic Tester

- Charging Device For Haldex Coupling 2 -VAS6291- or Charging Device For Haldex Coupling 2 -VAS6291A-

- Charging Device For Haldex Coupling 2 - Adapter 3 -VAS6291/3-

- Drip Tray

Caution

Caution

This procedure contains mandatory replaceable parts. Refer to component overview prior to starting procedure.

Mandatory Replacement Parts

- Plug - ATF check

Test Conditions:

- The rear final drive must be in the installed position.

- The vehicle must be level.

- Refer to → Chapter "Component Location Overview - Drain and Check Plugs, 0D3 Sport Differential"

- The ATF drain plug is installed and tightened. Tightening specification. Refer to → Fig. "ATF Drain Plugs on Rear Final Drive 0D3".

NOTICE

NOTICE

Using incorrect transmission fluid.

Risk of damaging the transmission.

- Only use transmission fluid as specified in the Parts Catalog.

- Use the -VAS6291A- to fill.

- The ATF filler tool must be clean and the ATF must not be mixed with any other oils.

- Lift the vehicle.

- Remove the ATF check plug -1-.

Tip:

- The ATF check plug -1- is located on the left side of the rear final drive. Identification "ATF" on the final drive housing -arrow-

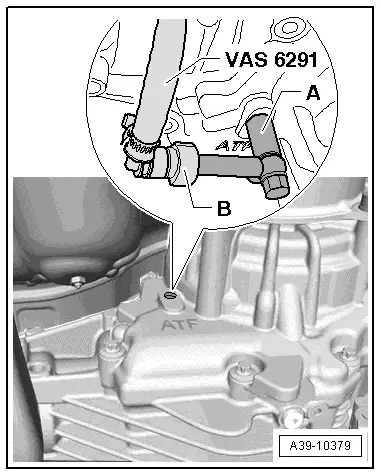

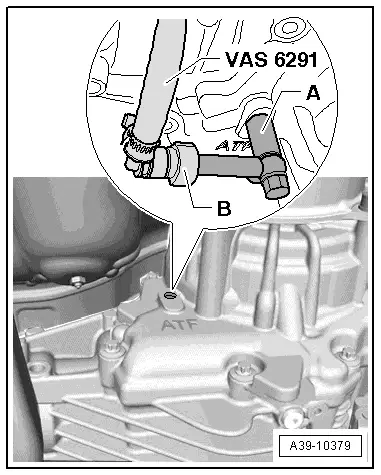

- Disconnect the adapter -A- and elbow -B-.

- Install in the adapter -A- all the way.

- Attach the elbow -B- to the adapter -A-.

- Route the hose over the left drive axle.

- The hose must not sag. It must be routed over the left rear wheel on the vehicle.

- Lower the vehicle.

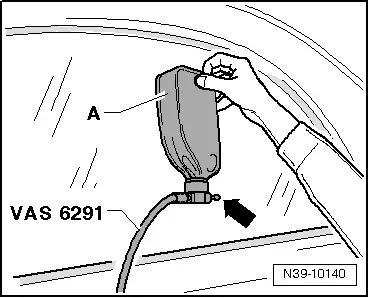

- Make sure that the valve -arrow- is closed.

- Install the oil container -A- on the -VAS6291A-.

- Open the valve -arrow- and hold the oil container as shown.

The hydraulic control unit and the left and right chambers in the rear final drive are now filled.

- When the correct filling of the rear final drive hydraulic control module ATF drips from the adapter -A-

If there still is no ATF in the adapter -A-:

- Continue filling until the level is correct.

When ATF starts to leak out of the adapter -A-:

- Lift the vehicle.

- Place the oil container for example on a tool box.

A portion of the excess oil runs back into the oil container.

- If no more ATF runs back, remove the -VAS6291A-.

- The oil level is correct when the rear final drive is filled up to the lower edge of the oil fill hole.

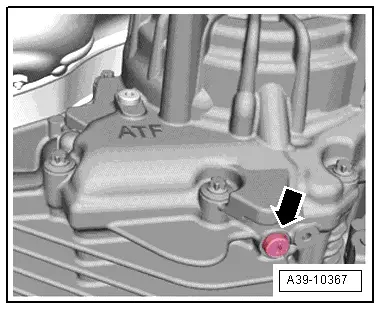

- Install the ATF check plug -arrow- hand-tight.

- Connect the Vehicle Diagnostic Tester and turn on the ignition.

- Select the function 22 - AWD Electronics in the Vehicle Diagnostic Tester under Guided Functions in the directory 22- ATF Filling.

- Follow all the instructions given by the Vehicle Diagnostic Tester exactly.

The system is filled and bled using the Vehicle Diagnostic Tester.

Tip:

- Repeat the filling process if the system detects there is still air inside the system after performing the 22 - ATF Filling function.

- Remove the ATF check plug -arrow- again.

Test Condition:

- The ATF level is correct when the rear final drive is filled up to the lower edge of the filler hole -arrow-.

- If necessary fill the ATF.

- In the DTC memory there is no entry and no "sporadic malfunction". Refer to Vehicle Diagnostic Tester.

- Install the new ATF check plug -arrow- and tighten. Tightening specification. Refer to → Fig. "ATF Drain Plugs on Rear Final Drive 0D3".