Audi Q7: Left Seal, Replacing

Left Seal, Replacing, 0DB, 0D2

Special tools and workshop equipment required

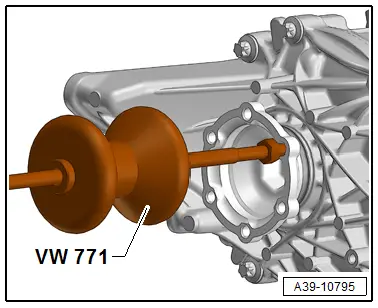

- Slide Hammer Set -VW771-

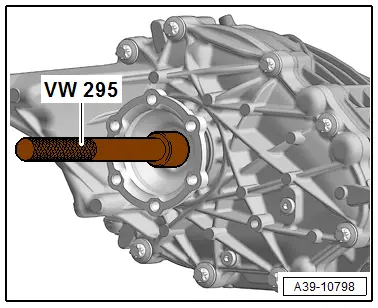

- Bearing/Bushing Installer - Multiple Use -VW295-

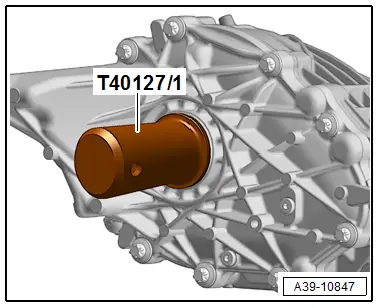

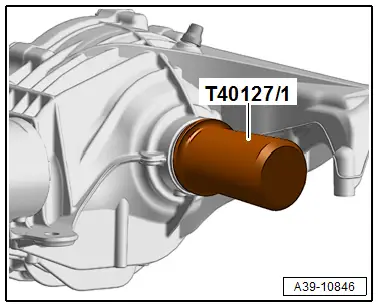

- Seal Installer - Double Radial Oil Seal -T40127/1-

- Sealing Grease -G 052 128 A1-

Caution

Caution

This procedure contains mandatory replaceable parts. Refer to component overview prior to starting procedure.

Mandatory Replacement Parts

- Circlip - Left Flange Shaft to Rear Final Drive

- The rear final drive is removed. Refer to → Chapter "Final Drive, Removing and Installing".

- Follow all general repair information. Refer to → Chapter "Repair Information".

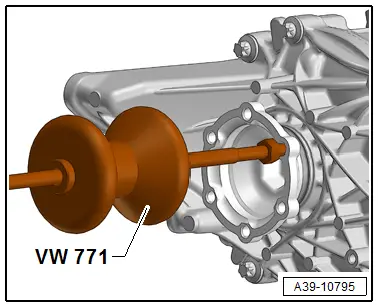

- Drive out the left flange shaft with the Slide Hammer Set -VW771-.

- Use a suitable tool to pry out the seal.

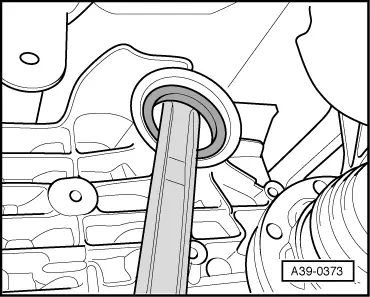

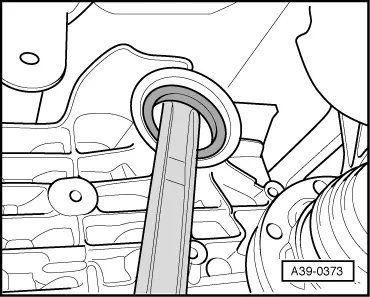

- Coat outer edge of the seal with gear oil.

- Fill the space between the sealing/dust lip halfway with Sealing Grease -G 052 128 A1-.

- Install the new shaft seal with Seal Installer - Double Radial Oil Seal -T40127/1- all the way. Do not the tilt the shaft seal while doing so.

- Clamp the flange shaft in a vise with protective jaws.

- Remove the old circlip.

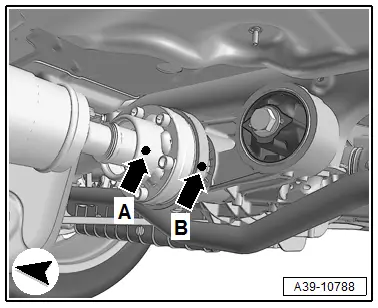

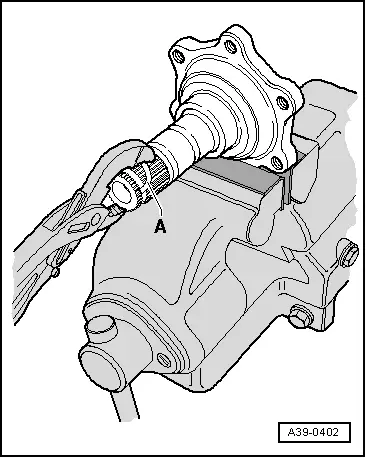

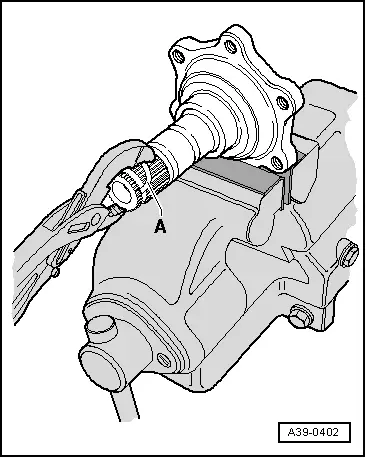

- Insert a new circlip -A- using Pliers in the groove on the flange shaft at the same time do not stretch the circlip.

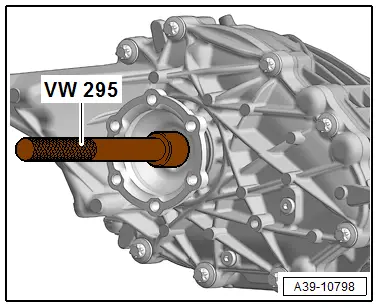

- Drive the flange shaft in using a - VW295-.

- Install the rear final drive. Refer to → Chapter "Final Drive, Removing and Installing".

- Check the rear final drive gear oil. Refer to → Chapter "Gear Oil, Checking Level".

Right Seal, Replacing

Right Seal, Replacing, 0DB, 0D2

Special tools and workshop equipment required

- Slide Hammer Set -VW771-

- Bearing/Bushing Installer - Multiple Use -VW295-

- Seal Installer - Double Radial Oil Seal -T40127/1-

- Sealing Grease -G 052 128 A1-

Caution

Caution

This procedure contains mandatory replaceable parts. Refer to component overview prior to starting procedure.

Mandatory Replacement Parts

- Circlip - Right Flange Shaft to Rear Final Drive

- The rear final drive is removed. Refer to → Chapter "Final Drive, Removing and Installing".

- Follow all general repair information. Refer to → Chapter "Repair Information".

- Drive out the left flange shaft with the Slide Hammer Set -VW771-.

- Use a suitable tool to pry out the seal.

- Coat outer edge of the seal with gear oil.

- Fill the space between the sealing/dust lip halfway with Sealing Grease -G 052 128 A1-.

- Install the new shaft seal with -T40127/1- all the way. Do not the tilt the shaft seal while doing so.

- Clamp the flange shaft in a vise with protective jaws.

- Remove the old circlip.

- Insert a new circlip -A- using Pliers in the groove on the flange shaft at the same time do not stretch the circlip.

- Drive the flange shaft in using a - VW295-.

- Install the rear final drive. Refer to → Chapter "Final Drive, Removing and Installing".

- Check the rear final drive gear oil. Refer to → Chapter "Gear Oil, Checking Level".

Input Shaft Seal, Replacing

Input Shaft Seal, Replacing, 0DB, 0D2

Special tools and workshop equipment required

- Puller - Multiple Use -VW391-

- Slide Hammer Set - Adapter 40 - VW771/40- from the Slide Hammer Set - VW771-

- Puller - Unit Injector -T10055-

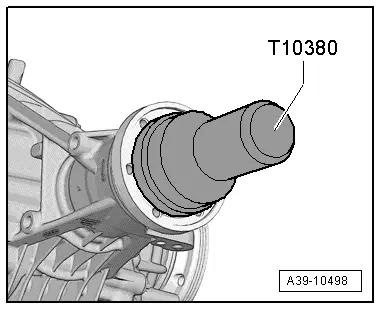

- Seal Installer - Hollow Shaft -T10380-

- -2-Puller - Unit Injector - Adapter 2 -T10055/2-

- Seal Installer - Input Shaft - Guide Sleeve -T40222/1-

- Inductive Heater -VAS6414-

or

- Commercially Available Hotplate with Digital Thermometer -VAS6519-

- Used Oil Collection and Extraction Unit -SMN372500-

- Sealing Grease -G 052 128 A1-

- Two M 8 x 30 Bolts

Caution

Caution

This procedure contains mandatory replaceable parts. Refer to component overview prior to starting procedure.

Mandatory Replacement Parts

- Circlip for Flange/Driveshaft

Removing

- The rear final drive is removed.

- Pay attention to the general repair information. Refer to → Chapter "Repair Information".

- Place the vehicle on a hoist.

Audi Q7

- Remove the center underbody trim panel. Refer to → Body Exterior; Rep. Gr.66; Underbody Trim Panel; Underbody Trim Panels, Removing and Installing.

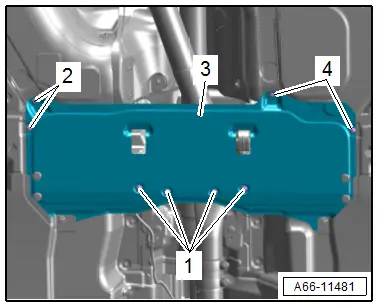

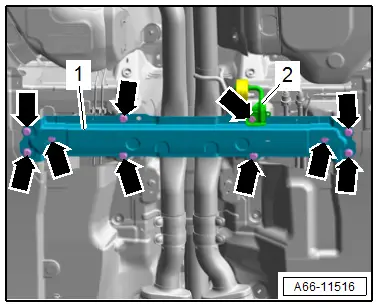

- Remove the bolts -arrows- and the crossmember -1-.

NOTICE

NOTICE

Incorrect handling can damage the coupling.

- Do not bend the coupling more than 10º.

- Do not load the coupling.

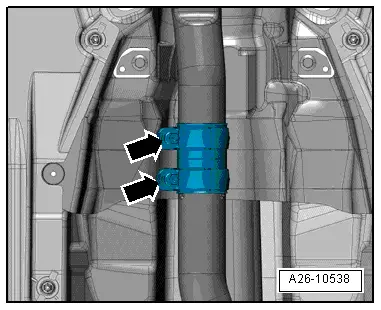

- Loosen the lock washer(s) -arrows- and separate the exhaust system.

- Tie up the front exhaust pipe(s) on the side to the underbody.

Audi A4

- Remove the rear section of the exhaust system. Refer to → Rep. Gr.26; Exhaust Pipes/Mufflers; Overview - Muffler.

Continuation for All Vehicles

- Remove the driveshaft on the rear final drive. Refer to → Chapter "Drive Shaft, Removing from Rear Final Drive and Installing".

- Tie the driveshaft to the side.

- Remove the High Temperature Grease in the flange/driveshaft.

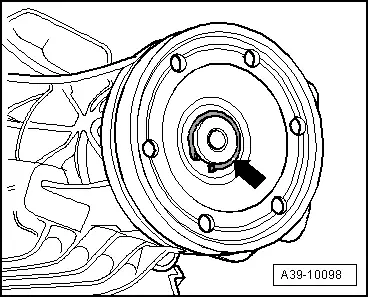

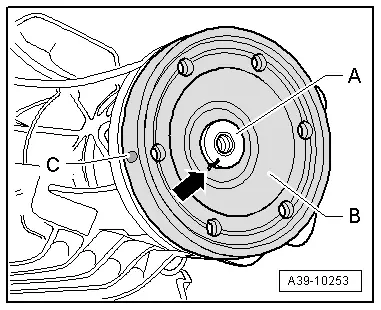

- Remove the circlip -arrow-.

- Replace the circlip with a new one of the same thickness if it is stretched or damaged. Allocation. Refer to the Parts Catalog.

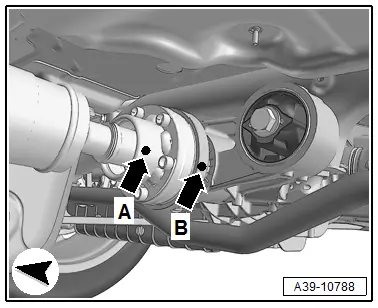

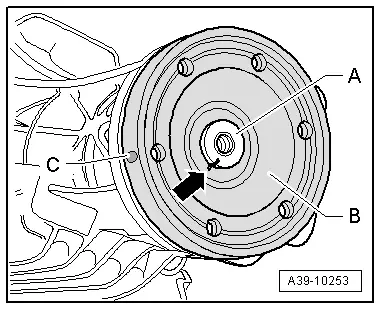

- Mark the position of the flange/driveshaft -B- on the pinion -A--arrow-.

- This marking -arrow- is needed so the colored dot -C- on the outer flange remains in its original position.

- This ensures the imbalance in the rear final drive will be as small as possible.

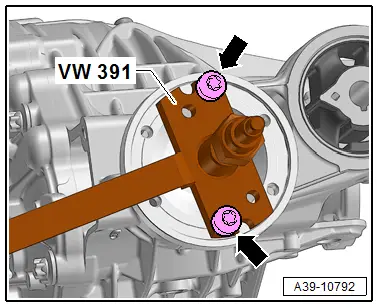

- Secure the -VW391- with Two M 8 x 30 Bolts-arrow- on the flange/driveshaft.

- Remove the flange/driveshaft with the - VW391-.

- Place the -SMN372500- underneath.

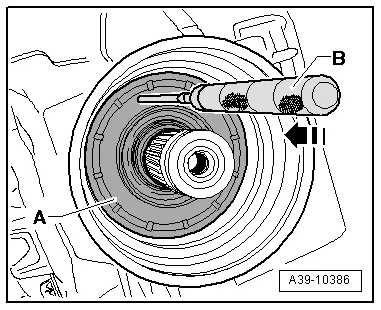

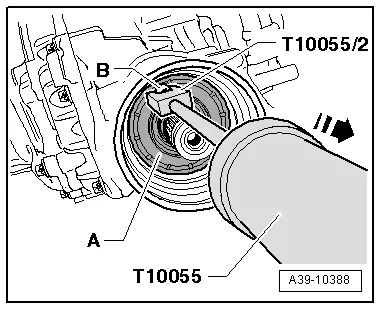

- Knock through the metal ledge of the shaft seal -A-, for example, with a scriber -B- in the direction of -arrow-.

- Then install a bolt -arrow- in this shaft seal opening -A-.

- Remove the shaft seal -A- for the flange/driveshaft over the bolt -B- in the direction of -arrow-.

Installing

Install in reverse order of removal. Note the following:

- Fill the space between the sealing/dust lip halfway with Sealing Grease -G 052 128 A1-.

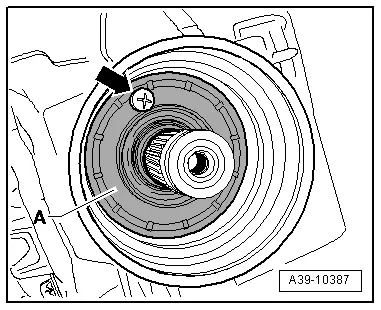

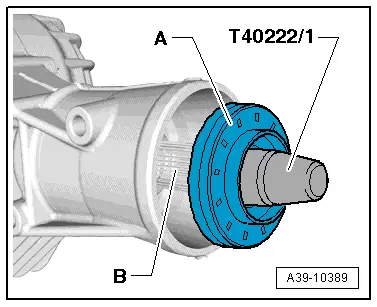

- Place the new shaft seal -A- on the -T40222/1-.

Tip:

- Make sure the shaft seal spring is in its installation position behind the sealing lip.

- Coat outer edge of the seal with gear oil.

- Push the -T40222/1- and the shaft seal -A- onto the pinion -B-.

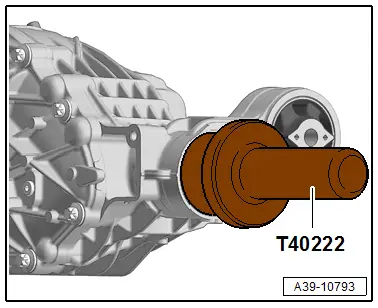

- Push in the new shaft seal to the "installation dimension" using the -T40222-.

Seal Installation Dimension on Final Drive 0DB:

- 25.5 mm +- 0.3 under housing outer edge

Seal Installation Dimension on Final Drive 0D2:

- 24.0 mm +- 0.3 under housing outer edge

- Remove the -T40222- and -T40222/1-.

CAUTION

CAUTION

Hot components.

Burning of hands is possible.

- Wear safety gloves.

- If using a Heating Plate the temperature must be observed using a -VAS6519-.

- Warm the flange/driveshaft -B- with a -VAS6414- or a Heating Plate to 115 ºC (239 ºF).

- Position the flange/driveshaft -B- on the pinion -A- so that the mark -arrow- is in a straight line.

- Install the flange/driveshaft with the -T10380-.

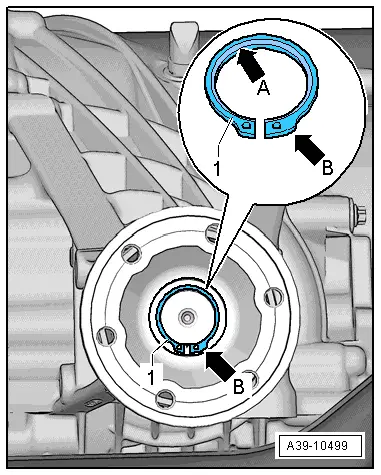

Install the circlip -1- as follows:

- Always replace the circlip -1-.

- The bevel on the inner diameter of the circlip -arrow A- faces out, toward the driveshaft.

- The wide tab on the circlip -arrow B- must be on the right side, as shown.

Note the following When Replacing the Flange/Driveshaft

- The locking ring -1- must be determined again.

- For this, determine and insert the thickest locking ring -1- that can still be installed in the groove. Refer to the Parts Catalog for the part number.

- Attach the driveshaft to the rear final drive. Refer to → Fig. "Install the Driveshaft on the Rear Final Drive.".

- Check the rear final drive gear oil. Refer to → Chapter "Gear Oil, Checking Level".

- Install the crossmember. Refer to → Body Exterior; Rep. Gr.66; Underbody Trim Panel; Overview - Underbody Trim Panels.

- Assemble the exhaust system. Refer to → Rep. Gr.26; Exhaust Pipes/Mufflers; Overview - Muffler.