Audi Q7: Boot, Replacing

Special tools and workshop equipment required

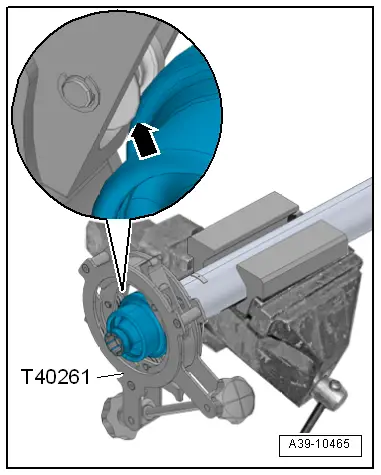

- Flanging Tool -T40261-

- Hose Clamp -23 to 35 mm Diameter-

Caution

Caution

This procedure contains mandatory replaceable parts. Refer to component overview prior to starting procedure.

Mandatory Replacement Parts

- O-ring - Driveshaft joint

Procedure

- Remove the driveshaft. Refer to → Chapter "Driveshaft, Removing and Installing".

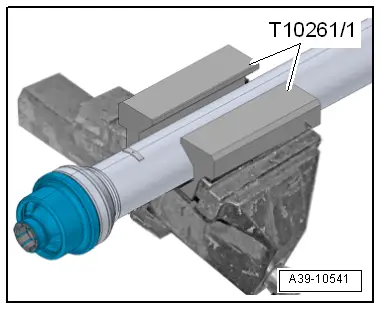

- Clamp the driveshaft with the -T40261/1- into the vise, as shown.

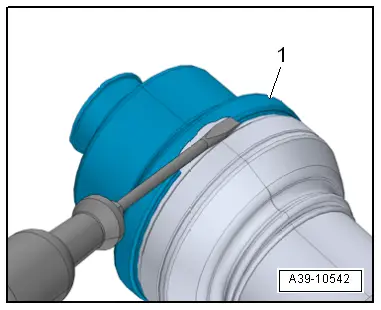

- Carefully loosen the metal sleeve flanging -1- from the driveshaft joint at one place with a screwdriver.

- The surface on the driveshaft joint must not be damaged.

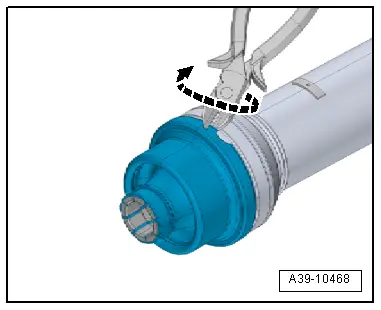

- Open the rest of the metal sleeve flanging in direction of -arrow- with a side cutter.

- Remove the old boot with the metal sleeve from the driveshaft joint.

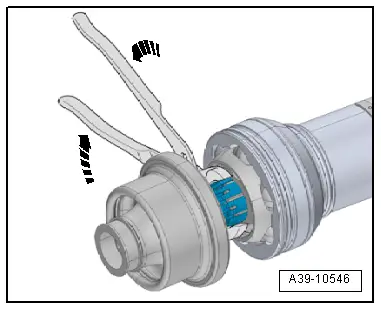

- Break the support ring with the water pump pliers in direction of -arrows- and remove the boot with the metal sleeve.

- The inside of the joint and the balls remain in the driveshaft joint.

- Wipe away any excess grease.

- Grease the driveshaft joint with grease from the installation kit.

- Fill with the same amount of grease, that has been clean off plus the amount that remains in the old boot.

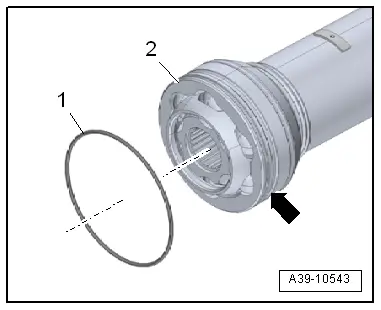

- Clean the sealing surface -arrow- on the driveshaft joint -2-.

- If there are scratches left behind after removing the old boot, smooth them out.

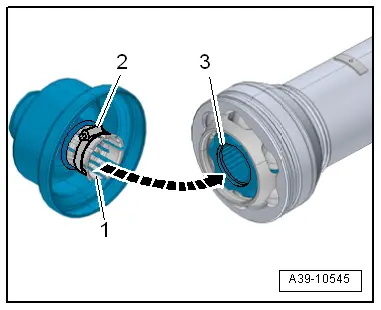

- Insert a new O-ring -1- in the groove.

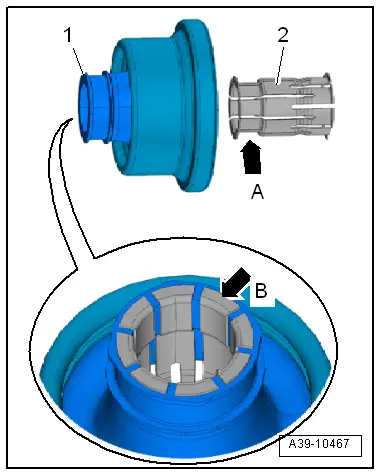

- Install the support ring -2- in the boot opening -1-.

- Direction of installation: the depression -arrow A- is slid into the boot.

- The guides for the support ring -arrow B- must be visible on the edge of the boot opening.

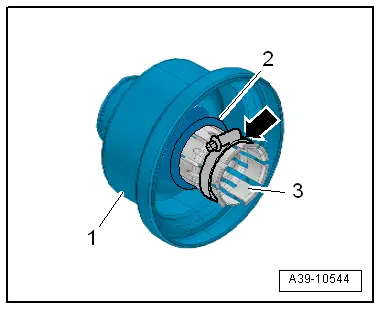

- Fold the boot -2- inward inside the metal sleeve -1-.

- Slide the hose clamp -arrow- onto the open guides for the support ring -3- as shown.

- The end of the support ring must be freed up.

- Tighten the hose clamp -2- until the support ring guides -1- are able to be inserted into the groove -3- of the inside of the joint.

- Loosen the hose clamp -2- and remove.

- The support ring guides must catch on the inside of the groove -arrow-.

- Slide the metal sleeve for the boot all the way onto the joint.

- Attach the -T40261- to the metal sleeve so that the guide roller stops -arrow- are touching the edge of the metal sleeve.

- Flange the metal sleeve by turning the -T40261- back and forth.

- The turning angle must be at least 90º when turning it back and forth.

- While turning it back and forth, turn the hand wheel for the -T40261-.

- The flanging is finished when the hand wheel for the -T40261- can only be turned if a lot of force is used.