Audi Q7: Filter, Removing and Installing

Special tools and workshop equipment required

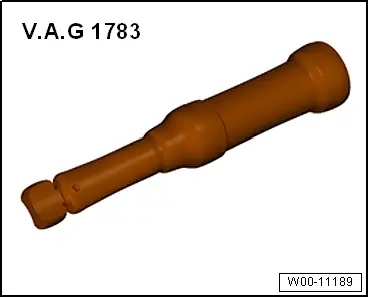

- Torque Wrench 1783 - 2-10Nm -VAG1783-

Removing

Note

Note

Follow the guidelines for clean working conditions. Refer to → Chapter "Guidelines for Clean Working Conditions".

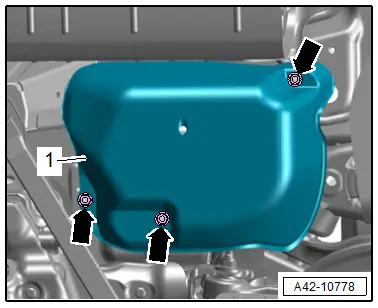

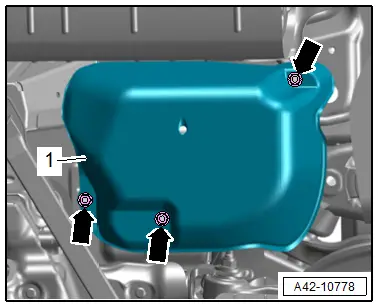

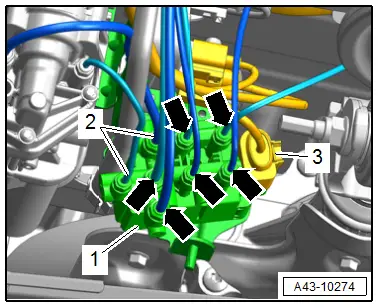

- Remove the nuts -arrows-, and remove the cover -1- for the air supply unit.

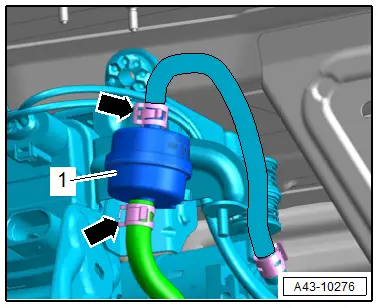

- Loosen the clamps -arrows-, remove the intake hoses and immediately protect them from dirt.

- Unclip the air filter -1- from the bracket and remove.

Installing

Install in reverse order of removal.

Tightening Specifications

- Refer to → Chapter "Overview - Air Supply Unit"

Solenoid Valve Block, Removing and Installing

Special tools and workshop equipment required

- Torque Wrench 1410 -VAG1410-

- Torque Wrench 1783 - 2-10Nm -VAG1783-

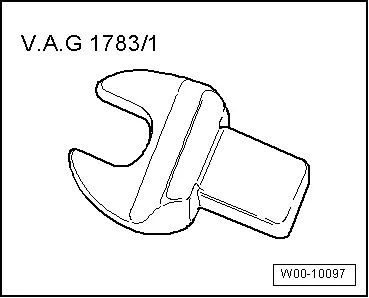

- Torque Wrench 1783 - Open Jaw - 10mm -VAG1783/1-

Removing

Note

Note

Follow the guidelines for clean working conditions. Refer to → Chapter "Guidelines for Clean Working Conditions".

- Vent the system. Refer to → Chapter "Air Suspension System, Filling and Bleeding".

- Switch off the ignition.

- Remove the nuts -arrows-, and remove the cover -1- for the air supply unit.

- Disconnect the connector -3- from the solenoid valve -1-.

- Remove the air lines -2- and -arrows- and protect them from dirt.

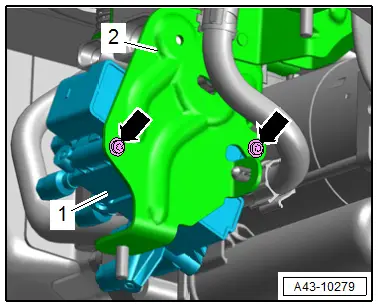

- Remove the bolts -arrows- and the solenoid valve -1- from the bracket -2-.

Installing

Install in reverse order of removal and note the following:

- Fill the system. Refer to → Chapter "Air Suspension System, Filling and Bleeding".

Tightening Specifications

- Refer to → Chapter "Overview - Air Supply Unit"

Pressure Reservoir, Removing and Installing

Special tools and workshop equipment required

- Torque Wrench 1783 - 2-10Nm -VAG1783-

Note

Note

The procedure for the left side of the vehicle is described.

Removing

Note

Note

Follow the guidelines for clean working conditions. Refer to → Chapter "Guidelines for Clean Working Conditions".

- Vent the system. Refer to → Chapter "Air Suspension System, Filling and Bleeding".

- Switch off the ignition.

- Remove the air duct to the vent from the B-pillar. Refer to → Body Interior; Rep. Gr.70; Vehicle Interior Trim Panels; Overview - B-Pillar Trim Panel.

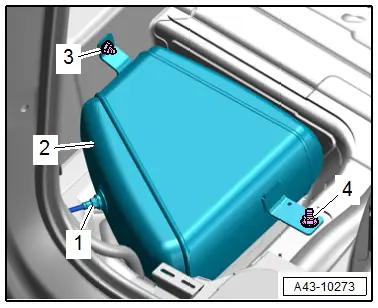

- Slowly loosen air line -1- on pressure reservoir -2- and allow air pressure to come down. After the air pressure has escaped, remove the air line.

- Remove the bolts -3- and nut -4- and remove the pressure reservoir.

Installing

Install in reverse order of removal and note the following:

- Fill the system. Refer to → Chapter "Air Suspension System, Filling and Bleeding".

Tightening Specifications

- Refer to → Fig. "Pressure Reservoir - Tightening Specification"

Special Tools

Special tools and workshop equipment required

- Torque Wrench 1410 -VAG1410-

- Torque Wrench 1783 - 2-10Nm -VAG1783-

- Torque Wrench 1783 - Open Jaw - 10mm -VAG1783/1-

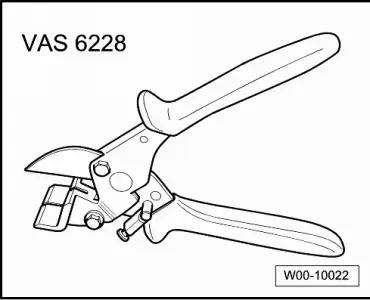

- Hose Cutting Pliers -VAS6228-

- If the Bonding Agent -D 355 205 A2- dries longer than 3 hours, then it must be primed again.