Audi Q7: Introduction

This revised information should supplement the knowledge and experience you already have.

With this information, we want to help you make as clear and certain a statement as possible concerning tire damage and complaints.

This chapter contains general information on tires and wheels.

Wheels are high-tech products which have been optimally matched to the operating conditions of modern vehicles.

As for all technically highly developed products, careful handling, care and maintenance are required for tires as well. Only then are the safety, performance and driving comfort guaranteed for the entire service life of the tire.

The tires are subject to a process of constant further development. As a result of modern construction techniques, finishing processes and constant quality checks, high-quality tires are produced. All tires approved by Audi have been tested by technical development and matched to the respective vehicle type in cooperation with the tire manufacturers.

Therefore, when replacing the tires, we recommend always to mount the approved and recommended tire brands.

Vehicle safety always has the highest priority. With regard to the various operating conditions, such as:

- Different speed ranges

- Winter and summer use

- Wet and dry roads

An optimal compromise must be found to ensure driver safety.

Every tire faces many different types of stress over distance and time. Therefore, it is important that the basic requirements for optimal use of tires are fulfilled.

The correct adjustment of the axle geometry is an important requirement for optimum service life of the tire. Therefore, the adjustment of the axle geometry must lie within the specified tolerance range.

Note

Note

There are many causes for tire damage and complaints. Therefore, it is very important to recognize whether the complaint arises from the tires or from other components.

The running characteristics of the tire change in the course of normal wear. Rolling noises and vibrations can result from this. These are not damage in the sense of tire defects, but rather symptoms resulting from use. These can be corrected, at least partially, by specific measures. In certain cases, rolling noise cannot be completely eliminated.

Tire Requirements

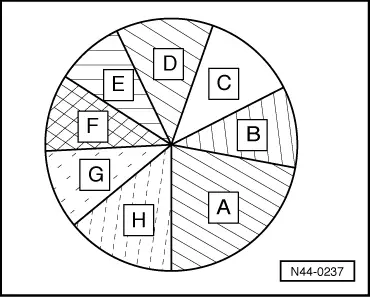

A - Wet braking behavior

B - Comfort

C - Steering precision

D - Driving stability

E - Tire weight

F - Service life expectancy

G - Rolling resistance

H - Hydroplaning

The pie chart represents the tire's performance. It shows how the extent of the demands A through H could be distributed in tire construction and rubber compound.

The improvement of one characteristic leads to the worsening of another one.

Example:

The improvement of wet braking behavior -A- leads to losses in comfort -B-, rolling resistance -G- and service life expectancy -F-.

The service life expectancy of car tires depends not only on the rubber compound and the tire construction. The operating conditions, circumstances specific to the vehicle and the driving style all have a strong influence on the tire's service life.

With modern vehicles and appropriate engines, especially gentle and economical but also extremely sporty driving is possible. Service life of 5,000 to 40,000 km (3,100 to 25,000 miles) and even more is possible.

Note

Note

Driving style is the decisive influencing factor on the life of the tires.

Tire Service Life, Influences

The following factors influence the service life of a tire in varying degrees.

- Speed

- Brakes

- Acceleration

- Cornering

- Driving Style

- Maintenance

- Tire Pressure

Area:

- Paving

- Exterior temperature/climate

Vehicle:

- Weight

- Tire Pressure

- Dynamic toe- + and camber values

Tire operating conditions

Speed range, wet or dry

Tire construction:

Winter/summer

Note

Note

Having the correct tire pressure in the tires also influences the life span of the tires.

Note

Note

Always make sure that the tires are inflated to the correct air pressure.

Maintenance (Tire Air Pressure)

The weight of the vehicle flattens the tire's contact patch. When the tire rolls, this results in deformation all around the circumference of the tread and the entire belt assembly. With low pressure, there is a greater deformation which results in more intense warming and greater rolling resistance. This all results in a greater wear and a greater safety risk.

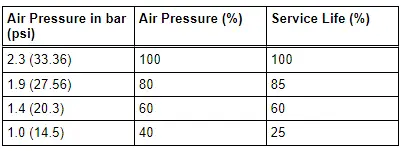

Example: specified series production tire pressure depending on load on cold tires

Excessive air pressure leads to greater wear at the center of the tire and reduced rolling comfort. It is recommended always to maintain the air pressure indicated by the manufacturer.

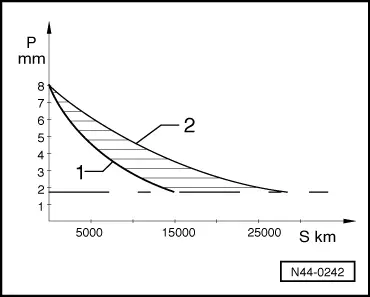

Diagram 1:

Tread depth over service life for vehicles with front wheel drive and V tires.

P - Tread Depth

S - Distance Driven

1 - Front Axle

2 - Rear Axle

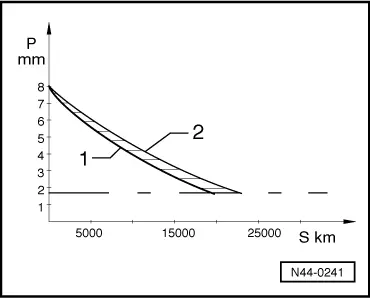

Diagram 2:

Tread depth over service life for vehicles with all wheel drive and V tires.

P - Tread Depth

S - Distance Driven

1 - Front Axle

2 - Rear Axle

Note

Note

- The diagrams presented cannot be applied in general.

- They only illustrate the wear characteristics on the front and rear axles as well as wear characteristics of front and all-wheel drive vehicles.

- Depending on operating conditions and chassis, the service life that can be attained may deviate substantially.

As can be seen in diagrams -1 and -2, for a given distance, more tread wears off tires with a complete tread than off tires which are quite worn. After the first 5,000 km (3100 miles), no conclusion can be made about the total service life because the wear curve is not linear.

On front-wheel drive vehicles, the front wheels must transmit the major portion of the lateral and braking forces as well as the steering and traction forces. Due to these demands, the front tires on front wheel vehicles wear more quickly than rear tires. Even usage of all tires is achieved by regularly exchanging front and rear tires. Rotating the wheels.

Driving Style

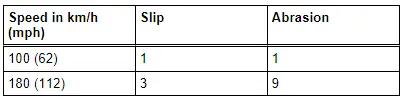

1. Constant driving without deceleration and acceleration.

Example:

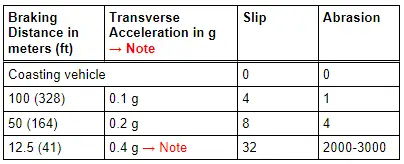

2. Brakes

The highest abrasion is achieved when braking.

Example: Braking at 50 km/h.

1) g = gravitational acceleration: 9.81 m/s2

2) A deceleration with 0.4 g corresponds to heavy braking.

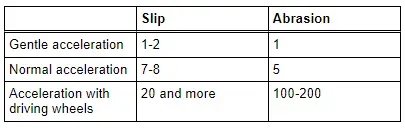

3. Acceleration (driving style)

The slip that occurs during a gentle acceleration from a stop is approximately the same as the slip that occurs at a steady speed of approximately 100 km/h (62 mph).

Example:

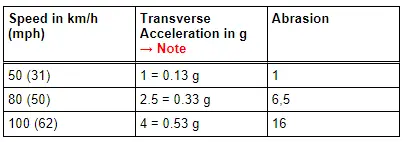

Cornering (driving style)

A sporty driving style and driving at higher speeds also cause greater wear when driving around curves.

In practice, this means doubling the speed in a curve leads to an increased abrasion by a factor of 16. This is the extra charge for driving faster.

Example: Driving around a curve with a radius of 150 m.

3) g = gravitational acceleration: 9.81 m/s2