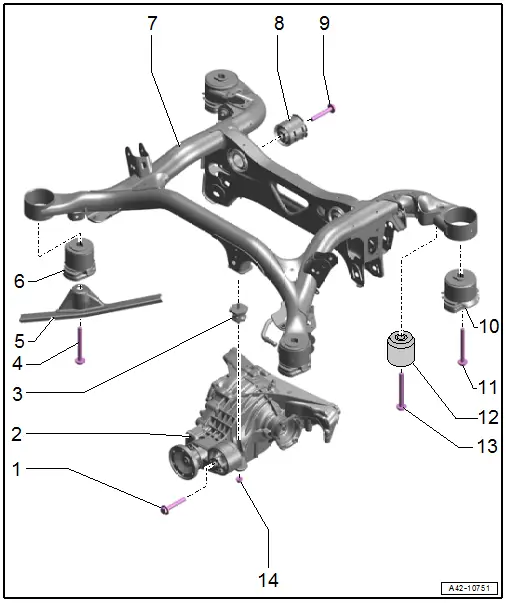

Audi Q7: Overview - Subframe

Audi Q7 (4M) 2016-2026 Workshop Manual / Chassis / Suspension, Wheels, Steering / Rear Suspension / Overview - Subframe

Caution

Caution

There is a risk of damaging the threads on the subframe threaded connection to the body.

- The subframe bolts on the body must not be loosened or tightened with an impact wrench.

- Always install all bolts by hand for the first few turns.

1 - Bolt

- Tightening specification. Refer to → Rep. Gr.10; Subframe Mount; Overview - Subframe Mount.

2 - Rear Final Drive

3 - Additional Bearing

- For the rear final drive

- Removing and installing. Refer to → Rep. Gr.10; Subframe Mount; Overview - Subframe Mount.

4 - Bolt

- 130 Nm +180º

- Replace after removing

5 - Diagonal Brace

- Overview. Refer to → Body Exterior; Rep. Gr.66; Underbody Trim Panel.

6 - Front Hydraulic Bonded Rubber Bushing

- For the subframe

- Removing and Installing. Refer to → Chapter "Subframe Front Hydraulic Bonded Rubber Bushing, Replacing".

- Installation position. Refer to → Fig. "Subframe Hydraulic Front Bonded Rubber Bushing Installation Position".

7 - Subframe

- Removing and installing. Refer to → Chapter "Subframe, Removing and Installing".

8 - Rear Bonded Rubber Bushing

- For the rear final drive

- Removing and installing. Refer to → Chapter "Rear Bonded Rubber Bushing for Rear Final Drive, Removing and Installing".

- Installation position. Refer to → Fig. "Rear Bonded Rubber Bushings Installation Position For The Rear Final Drive".

9 - Bolt

- Tightening specification. Refer to → Rep. Gr.10; Subframe Mount; Overview - Subframe Mount.

10 - Rear Bonded Rubber Bushing

- For the subframe

11 - Bolt

- 130 Nm +180º

- Replace after removing

12 - Vibration Damper

- Installation position. Refer to → Fig. "Vibration Damper Installation Position".

13 - Bolt

- 50 Nm +180º

- Replace after removing

14 - Nut

- Tightening specification. Refer to → Rep. Gr.10; Subframe Mount; Overview - Subframe Mount.

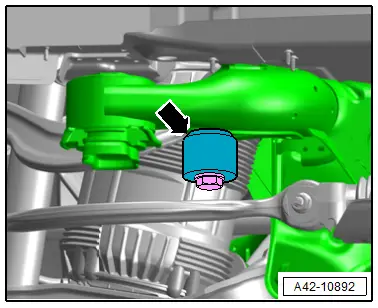

Vibration Damper Installation Position

- The beveled surface -arrow- must point upward.

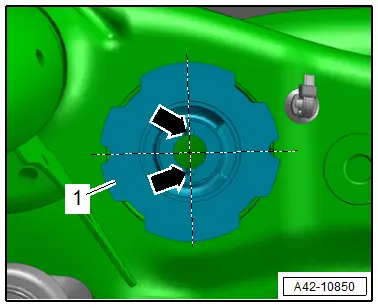

Subframe Hydraulic Front Bonded Rubber Bushing Installation Position

- The groves -arrows- are perpendicular to the direction of travel.

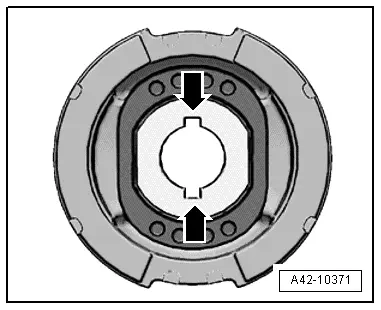

Rear Bonded Rubber Bushings Installation Position For The Rear Final Drive.

- The grooves -arrows- on the bonded rubber bushings -1- are at a right angle.