Audi Q7: Peripheral Camera, Calibrating

Calibration Device - VAS721001-, Installing and Aligning

After performing service work on the vehicle, it may be necessary to calibrate the peripheral camera system. In detail, this is the case after:

- Replacing one or more cameras

- Peripheral Camera Control Module -J928- replacement

- Flash the software from the Peripheral Camera Control Module -J928-

- Record the data set on the Peripheral Camera Control Module -J928-

- Repair work on components in which a camera is installed or that influence the component location of the camera

- Wheel Alignments

- When adjusting the overlap range of the individual cameras

- The standing height of one axle changes by more than 5 mm

- The standing height of the entire vehicle changes by more than 10 mm

Requirement for the Calibration of the Vehicle

- Camera lens must be cleaned, only clean the camera lenses with a wet towel.

- Check the camera images on the Front Information Display Control Head -J685-. Replace the camera if the images are unclear because the camera has been damaged. Check the fastener for the camera if the image is low.

- Make sure both exterior rearview mirrors are folded out.

- The parking brake must be set.

- The steering wheel must be in the 0 position and the wheels must be straight.

- All doors and the rear lid must be closed.

- No one should be in the vehicle.

- The vehicle must not be loaded (curb weight).

- The battery charger is connected, the battery charger must not be in the view of the camera.

- Ignition switched on.

- The system is active and is displayed on the Front Information Display Control Head -J685-.

- Do not move the vehicle during the calibration process.

Requirements for the Calibration Equipment/Calibration Environment

- flat calibration surface

- Do not use any objects in the environment of the calibration field, to prevent a false recognition of lines

- Even light (no headlamps or direct illumination), prevent strong light differences

Special tools and workshop equipment required

- Calibration System -VAS721001-

- Vehicle Diagnostic Tester

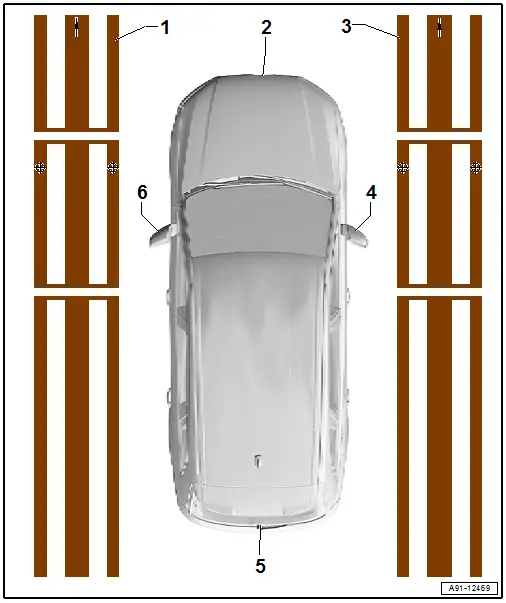

Overview of the Installed Calibration System -VAS721001-.

WARNING

WARNING

Make sure light does not reflect off the Calibration System -VAS721001-.

Reflections affect the camera and may make it impossible to perform the calibration.

1 - Left Calibration Device

2 - Front Peripheral Camera -R243-

- Calibrating. Refer to → Chapter "Peripheral Camera, Calibrating".

3 - Right Calibration Device

4 - Right Peripheral Camera -R245-

- Calibrating. Refer to → Chapter "Peripheral Camera, Calibrating".

5 - Rear Peripheral Camera -R246-

- Calibrating. Refer to → Chapter "Peripheral Camera, Calibrating".

6 - Left Peripheral Camera -R244-

- Calibrating. Refer to → Chapter "Peripheral Camera, Calibrating".

Peripheral Camera, Calibrating

- The vehicle must be on a level surface.

- Set-up the requirements for the calibration equipment/calibration environment.

- Set-up the requirement for the vehicle.

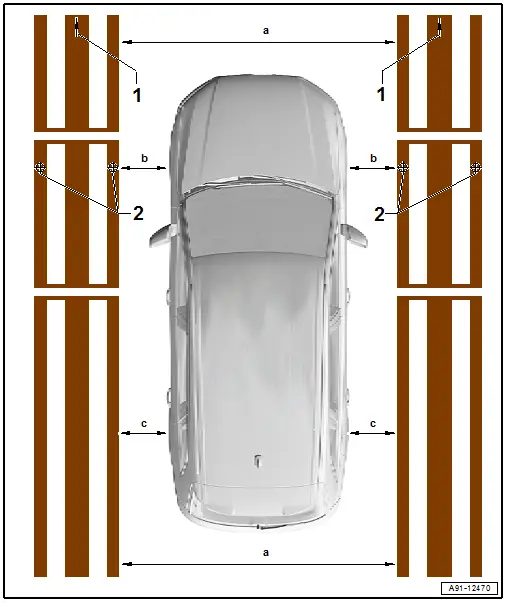

- Roll out the Calibration System -VAS721001- at the left and right near the vehicle.

- The arrows -1- in the Calibration System -VAS721001- points in the direction of travel.

- Install the rear and front clamping strip on the Calibration System -VAS721001-.

- Align the crosshairs -2- on the Calibration System -VAS721001- to the front axle of the vehicle (center front wheel).

- Align both calibration devices parallel. The vehicle must be located in the center between both calibration devices.

Pay attention to the following measurement requirements:

- Dimension -a- 2000 to 2500 mm +- 5 mm, front and rear the same

- The dimension -b- must be the same on both sides

- The dimension -c- must be the same on both sides

- Connect the Vehicle Diagnostic Tester.

Calibrating

- Select the Diagnostic mode and start the diagnosis.

- Select the Test plan tab.

- Press the Select individual tests button and select the following one after the other:

- Body

- Electrical Equipment

- 01 - OBD-capable systems

- 6C - peripheral camera control module | J928

- 6C - peripheral camera control module, functions

- 6C - Calibration, (Repair Group 91)

From here, the Vehicle Diagnostic Tester advances the calibration procedure forward.

WARNING

WARNING

Make sure light does not reflect off the Peripheral Camera Calibration Device -VAS6350/6-.

Reflections affect the camera and may make it impossible to perform the calibration.