Audi Q7: Vehicles with Restrictor, Receiver/Dryer and A/C Compressor Regulator Valve -N280-, Checking Pressures, Externally Regulated Compressor

General Information

Note

Note

- Connect the Air Conditioning (A/C) service station. Refer to → Chapter "A/C Service Station, Connecting".

- Observe the test requirements. Refer to → Chapter "Pressures, Checking".

- If a malfunction occurs at only one evaporator in vehicles with two evaporators, also check pressures in the refrigerant circuit, are these OK? Check the line connection between the evaporator in question and the exit of line connection at distribution point of refrigerant lines (for constriction). If no malfunction can be detected, discharge the refrigerant circuit and charge it with the specified refrigerant quantity. Then check pressures and cooling performance of A/C system again; if the malfunction occurs again, replace the expansion valve which is prematurely switched by the malfunctioning evaporator. Refer to → Heating, Ventilation and Air Conditioning; Rep. Gr.87; System Overview - Refrigerant Circuit (vehicle-specific repair manual).

- With the ignition switched off, check the pressure in the refrigerant circuit (using the service station). Refer to → Chapter "Refrigerant Circuit, Checking Pressure with Service Station".

The pressures with the ignition turned off meet the specifications.

- Start the engine.

- Bring the engine speed up to 2000 RPM.

- Observe the pressure gauge of the service station.

Note

Note

- Switching pressures for actuation of A/C Compressor Regulator Valve -N280- and Radiator Fan -V7- are vehicle-specific.

- Pressures must be measured at service connections; component locations of these connections are vehicle-specific. Refer to → Heating, Ventilation and Air Conditioning; Rep. Gr.87; System Overview - Refrigerant Circuit (vehicle-specific repair manual).

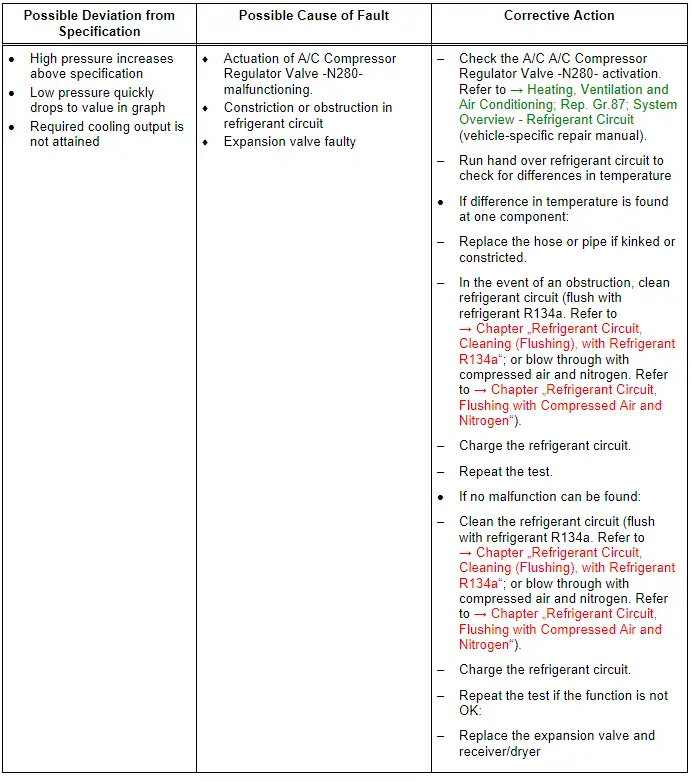

Specified Values for Refrigerant Circuit Pressures

High-Pressure Side:

Increasing from initial pressure (when connecting the pressure gauges) to a maximum of 20 bar (290 psi).

Low Pressure:

Decreasing from initial pressure (when connecting pressure gauges) to the value in the graph.

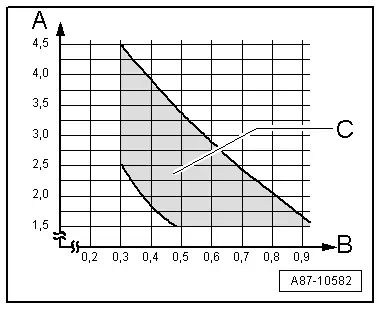

A - Low pressure (measured at service connection) in bar (psi)

B - Control current for A/C Compressor Regulator Valve -N280- in amps.

C - Permissible tolerance range (applicable to compressor capacity utilization of 10 to 90%)

Note

Note

- If high cooling output is needed (for example, the outside temperature is very high, the blower speed it set on high but the engine RPMs are low), then the A/C compressor will not bring the pressure on the low pressure side to the value specified in the diagram -C- (for example, for a certain time after turning on the A/C). The A/C compressor is actuated with maximum specified control current, however delivery volume is no longer sufficient at this engine speed to reduce pressure on low-pressure side to value in graph. To check the A/C compressor control under these conditions, for example, the fresh air blower is controlled only with approximately 40% of the maximum voltage, check the pressures at a lower fresh air blower speed. Use the Vehicle Diagnostic Tester ("OBD" or "Guided Fault Finding for the A/C system") and → Heating, Ventilation and Air Conditioning; Rep. Gr.00; Repair Instructions; Checking Cooling Output or →Heating, Ventilation and Air Conditioning; Rep. Gr.87 (vehicle-specific repair manual).

- Under unfavorable conditions (very high ambient temperatures, high humidity), pressure on high-pressure side may increase to max. 29 bar (421 psi).

- Control current -B- is displayed in measured value block of A/C Control Head -E87- or control head, Climatronic Control Module -J255-.

- The high pressure measured from the High Pressure Sensor -G65- (or the A/C Pressure/Temperature Sensor -G395- or the Refrigerant Circuit Pressure Sensor - G805-) is displayed as the measured value (from the Front A/C Display Control Head -E87-, the A/C Control Module -J301- or the display and control unit, and the A/C Control Module -J255-).

- Low pressure settles depending on control current for A/C Compressor Regulator Valve -N280- and control characteristic of expansion valve within compressor output range in tolerance range.

- Under unfavorable conditions (very high ambient temperatures, high humidity), compressor output may not always be sufficient to attain the specified value.

- If compressor capacity utilization is greater than 90%, pressure on low-pressure side may be in excess of tolerance range "C" shown in graph (compressor output no longer sufficient).

- The specified operating current for the A/C Compressor Regulator Valve -N280- must be greater than 0.3 A in order to ensure reliable regulator valve actuation.

- In "maximum cooling output" setting, control current for A/C Compressor Regulator Valve -N280- is regulated to approximately 0.65 A (up to 0.85 A). This measured value is vehicle-specific and displayed in the measured value block.

- At absolute pressure, 0 bar/psi corresponds to absolute vacuum. Normal ambient pressure corresponds to 1 bar (14.5 psi) absolute pressure. On the scales of most pressure gauges, 0 bar/psi corresponds to an absolute pressure of 1 bar (14.5 psi) (can be seen from -1 bar (-14.5 psi) mark below 0). Use the Vehicle Diagnostic Tester ("OBD" or "Guided Fault Finding for the A/C System") and → Heating, Ventilation and Air Conditioning; Rep. Gr.00; Repair Instructions; Checking Cooling Output or →Heating, Ventilation and Air Conditioning; Rep. Gr.87 (vehicle-specific repair manual).

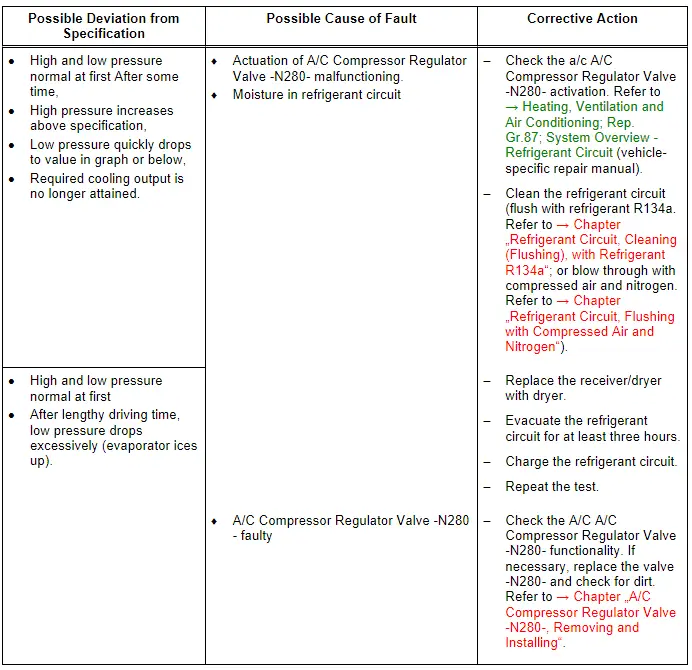

Note

Note

- If no fault is found with this malfunction, clean the refrigerant circuit (flush using refrigerant R134a. Refer to → Chapter "Refrigerant Circuit, Cleaning (Flushing), with Refrigerant R134a"; or blow through using compressed air and nitrogen. Refer to → Chapter "Refrigerant Circuit, Flushing with Compressed Air and Nitrogen".

- Check the measured values from the Evaporator Vent Temperature Sensor -G263- and the -N280- control. If measured value of Evaporator Vent Temperature Sensor -G263- is not OK, evaporator may ice up or cooling output is not attained.

- If air conditioner operation is not OK when test is repeated after replacing expansion valve, install old expansion valve, clean refrigerant circuit (flush using refrigerant R134a. Refer to → Chapter "Refrigerant Circuit, Cleaning (Flushing), with Refrigerant R134a"; or blow through using compressed air and nitrogen. Refer to → Chapter "Refrigerant Circuit, Flushing with Compressed Air and Nitrogen". Then replace the A/C compressor and receiver/dryer.

- With this malfunction, evaporator may ice up although the quantity of refrigerant in circuit is OK.

- If the expansion valve is malfunctioning (permanently closed or does not open sufficiently), the A/C A/C Compressor Regulator Valve -N280- is actuated to maximum output and low pressure drops to value in graph or below (compressor draws off refrigerant from low-pressure side). Since refrigerant cannot flow via expansion valve, cooling output is not attained, high pressure may also not increase or only increase slightly due to the absence of energy Vehicle Diagnostic Tester ("OBD" or "Guided Fault Finding for the A/C System") and → Heating, Ventilation and Air Conditioning; Rep. Gr.00; Repair Instructions; Checking Cooling Output or →Heating, Ventilation and Air Conditioning; Rep. Gr.87 (vehicle-specific repair manual).

Note

Note

- Make sure the A/C compressor (the A/C compressor shaft) is actually being driven by the belt pulley/drive unit → Heating, Ventilation and Air Conditioning; Rep. Gr.87; A/C Compressor (vehicle-specific repair manual).

- As of MY 2012, certain engines and A/C compressors that in addition to the A/C A/C Compressor Regulator Valve -N280-, have an A/C clutch -N25- attached to the belt pulley. Make sure the A/C A/C Compressor Regulator Valve -N25- is indeed being actuated and the A/C compressor (A/C compressor shaft) is being driven by the belt pulley. Refer to → Heating, Ventilation and Air Conditioning; Rep. Gr.87; A/C Compressor (vehicle-specific repair manual) and to the Parts Catalog.

Note

Note

- If the function of the A/C system is not OK when the test is repeated, replace the expansion valve and receiver/dryer.

- With this malfunction, evaporator may ice up although the quantity of refrigerant in circuit is OK.

- If expansion valve is malfunctioning (permanently closed or does not open sufficiently), AA/C Compressor Regulator Valve -N280- is actuated to maximum output and low pressure drops to value in graph or below (compressor draws off refrigerant from low-pressure side). Since refrigerant cannot flow via expansion valve, cooling output is not attained, high pressure may also not increase or only increase slightly due to the absence of energy. Use the Vehicle Diagnostic Tester ("OBD" or "Guided Fault Finding for the A/C System") and → Heating, Ventilation and Air Conditioning; Rep. Gr.00; Repair Instructions; Checking Cooling Output or →Heating, Ventilation and Air Conditioning; Rep. Gr.87 (vehicle-specific repair manual).

- If there is too much refrigerant oil in the circuit, the compressor must be drained and the receiver/dryer must be replaced. After cleaning the refrigerant circuit (flushing with refrigerant R134a. Refer to → Chapter "Refrigerant Circuit, Cleaning (Flushing), with Refrigerant R134a"; or blowing through using compressed air and nitrogen. Refer to → Chapter "Refrigerant Circuit, Flushing with Compressed Air and Nitrogen"), the correct quantity of refrigerant oil is filled into the circuit. Refer to → Chapter "Approved Refrigerant Oils and Capacities".

Note

Note

- It is not initially necessary to clean the refrigerant circuit (flush using refrigerant R134a. Refer to → Chapter "Refrigerant Circuit, Cleaning (Flushing), with Refrigerant R134a" or blow through using compressed air and nitrogen. Refer to → Chapter "Refrigerant Circuit, Flushing with Compressed Air and Nitrogen" when this problem occurs since normally there is only a small quantity of moisture in the system which can be removed by lengthy evacuation.

- If a problem involving moisture in refrigerant circuit only occurs after a lengthy operating period or only infrequently (low pressure drops below specification and evaporator ices up), it is sufficient to replace the dryer installed in receiver/dryer (adjust quantity of refrigerant oil). Refrigerant circuit is then to be evacuated for at least three hours.

- With this malfunction, evaporator may ice up although the quantity of refrigerant in circuit is OK.

- Problem with Evaporator Vent Temperature Sensor -G263- can also cause icing-up of refrigerant circuit. If this problem is encountered, also pay attention to measured value of Evaporator Vent Temperature Sensor -G263-. Use the Vehicle Diagnostic Tester ("OBD" or "Guided Fault Finding" for the A/C System) and → Heating, Ventilation and Air Conditioning; Rep. Gr.00; Repair Instructions; Checking Cooling Output or →Heating, Ventilation and Air Conditioning; Rep. Gr.87 (vehicle-specific repair manual).

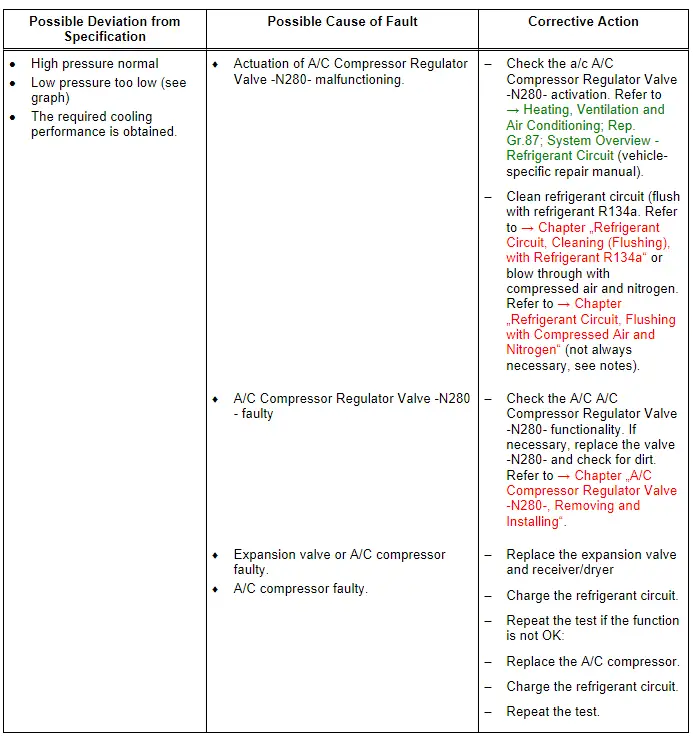

Note

Note

- For the malfunction "high pressure normal, low pressure too low", note the following: With this malfunction, evaporator may ice up although the quantity of refrigerant in circuit is OK.

- If the problem is with the -N280- A/C A/C Compressor Regulator Valve (regulator valve is not actuated but A/C compressor operates nevertheless), refrigerant circuit does not have to be cleaned (flush with refrigerant R134a. Refer to → Chapter "Refrigerant Circuit, Cleaning (Flushing), with Refrigerant R134a"; or blow through using compressed air and nitrogen. Refer to → Chapter "Refrigerant Circuit, Flushing with Compressed Air and Nitrogen"). In this case, it is sufficient to replace the A/C compressor (observe quantity of refrigerant oil in A/C compressor).

- If the expansion valve is malfunctioning (permanently closed or does not open sufficiently), the A/C A/C Compressor Regulator Valve -N280- is actuated to maximum output and low pressure drops to value in graph or below (compressor draws off refrigerant from low-pressure side). As however refrigerant cannot flow via the expansion valve, the cooling output is not attained and high pressure may also not increase or only increase slightly due to the absence of energy conversion.

- Check the measured values from the Evaporator Vent Temperature Sensor -G263- and the -N280- control. If the measured value from the Evaporator Vent Temperature Sensor -G263- is incorrect, the evaporator may ice up or cooling output is not attained. Use the Vehicle Diagnostic Tester ("OBD" or "Guided Fault Finding for the A/C System") and → Heating, Ventilation and Air Conditioning; Rep. Gr.00; Repair Instructions; Checking Cooling Output or →Heating, Ventilation and Air Conditioning; Rep. Gr.87 (vehicle-specific repair manual).

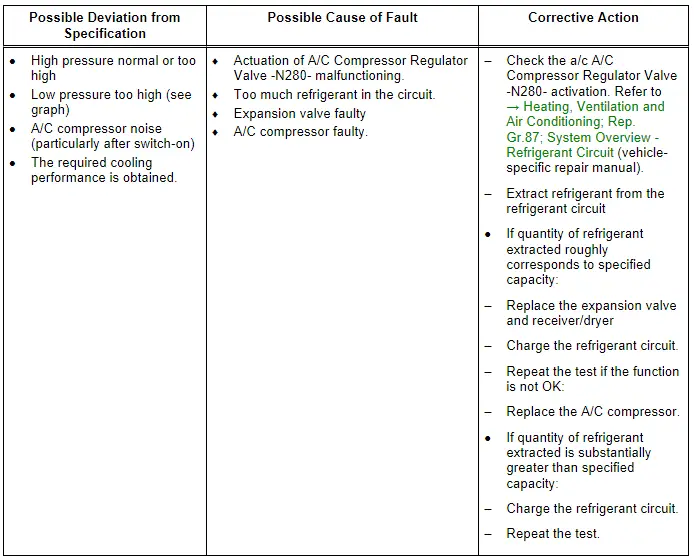

Note

Note

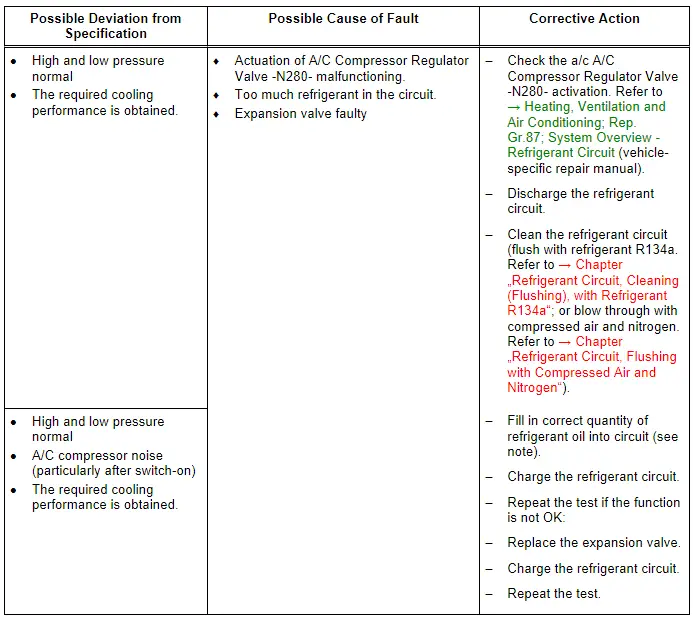

- This fault may also be caused by too much refrigerant oil in the circuit. Overfilling with refrigerant oil can occur if, for example, the compressor has been replaced without adjusting the quantity of refrigerant oil.

- If the expansion valve is malfunctioning (permanently closed or does not open sufficiently), the A/C A/C Compressor Regulator Valve -N280- is actuated to maximum output and low pressure drops to value in graph or below (compressor draws off refrigerant from low-pressure side). Since refrigerant cannot flow via expansion valve, cooling output is not attained, high pressure may also not increase or only increase slightly due to the absence of energy. Use the Vehicle Diagnostic Tester ("OBD" or "Guided Fault Finding for the A/C System") and → Heating, Ventilation and Air Conditioning; Rep. Gr.00; Repair Instructions; Checking Cooling Output or →Heating, Ventilation and Air Conditioning; Rep. Gr.87 (vehicle-specific repair manual).

Note

Note

- Overfilling with refrigerant oil can occur if, for example, the compressor has been replaced without adjusting the quantity of refrigerant oil.

- If expansion valve is malfunctioning (permanently open), evaporator temperature is no longer regulated such that only refrigerant in gaseous state exits from the evaporator. Under certain usage conditions, liquid droplets may then be drawn in by the compressor and cause noise (liquid cannot be compressed).

- If there is too much refrigerant oil in the circuit, the compressor must be drained and the receiver/dryer must be replaced. After cleaning the refrigerant circuit (flushing with refrigerant R134a. Refer to → Chapter "Refrigerant Circuit, Cleaning (Flushing), with Refrigerant R134a"; or blowing through using compressed air and nitrogen. Refer to → Chapter "Refrigerant Circuit, Flushing with Compressed Air and Nitrogen"), the correct quantity of refrigerant oil is filled into the circuit. Refer to → Chapter "Approved Refrigerant Oils and Capacities".