Audi Q7: Drive Axle, Disassembling and Assembling

Drive Axle, Disassembling and Assembling, Triple Roller Joint AAR 3300i

Special tools and workshop equipment required

- Press Plate -VW401-

- Press Plate -VW402-

- Press Piece - Rod -VW408A-

- Press Piece - Rod -VW411-

- Press Piece - 37mm -VW416B-

- Press Piece - Multiple Use -VW447H-

- Slide Hammer Set -VW771-

- Tripod Joint Tool -T10065-

- Triple Roller Assembly Tool -T40018-

- Pneumatic Hydraulic Press -VAS6654-, not illustrated

- Commercially available locking ring pliers.

Disassembling

- Clamp the drive axle horizontally in a vise with protective covers.

Note

Note

Make sure that drive axle is not damaged.

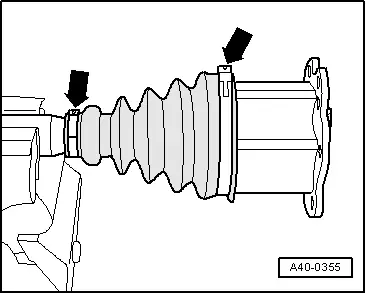

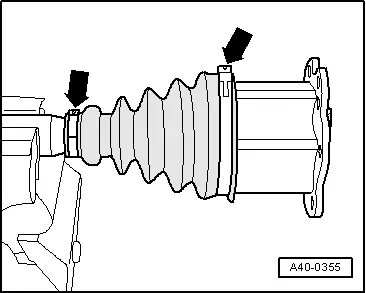

- Open clamps -arrows-.

- Slide back protective boot.

Caution

Caution

Risk of noises when driving due to a changed installation position.

For reinstallation mark the installation position of the joint to the drive axle using for example a waterproof marker.

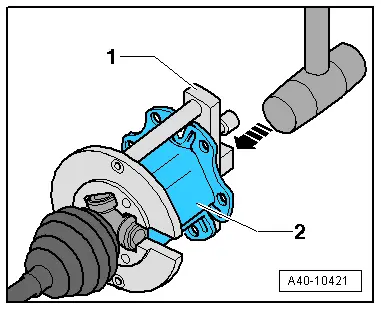

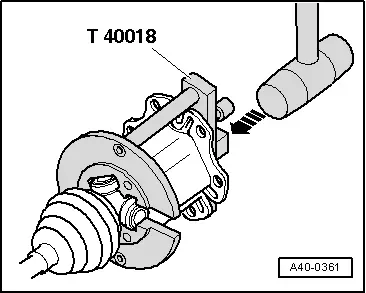

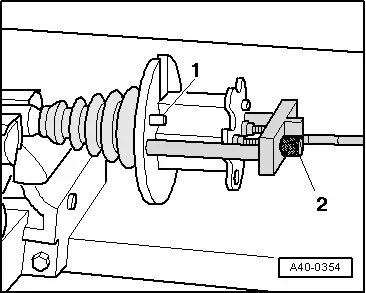

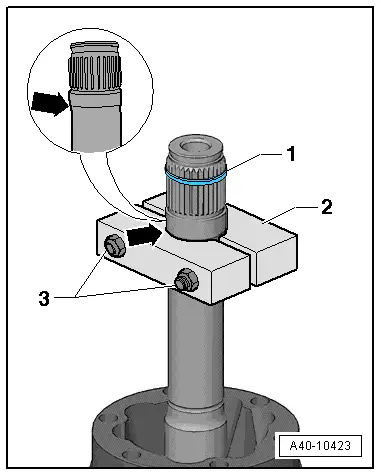

- Guide the Triple Roller Assembly Tool -T40018- behind the joint.

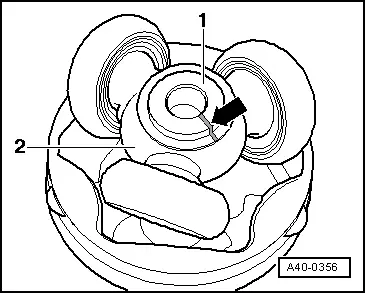

- The guide pins -1- must contact the outer joint.

- Move the Triple Roller Assembly Tool -T40018- to the joint until stop by turning knurled bolts -2-.

Note

Note

- Secure the joint without play in the Triple Roller Assembly Tool -T40018-.

- Only tighten the knurled bolts hand tight.

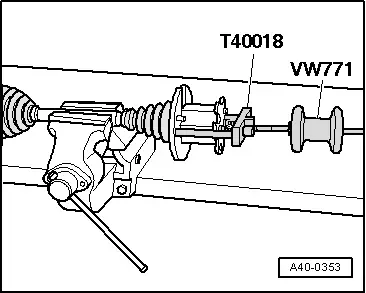

- Install the Slide Hammer Set -VW771- in the Triple Roller Assembly Tool -T40018-.

- Remove the joint horizontally with the Slide Hammer Set -VW771-.

- Leave the joint in the Triple Roller Assembly Tool -T40018-.

Caution

Caution

Risk of noises when driving due to a changed installation position.

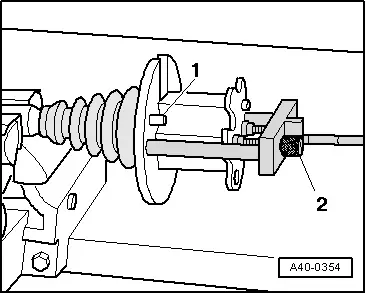

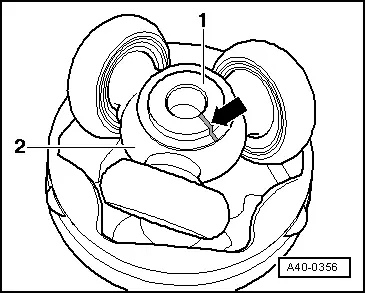

For reinstallation mark the installation position of the drive axle -1- to the triple roller star -2- using for example a waterproof marker.

- Remove grease with lint-free cloth.

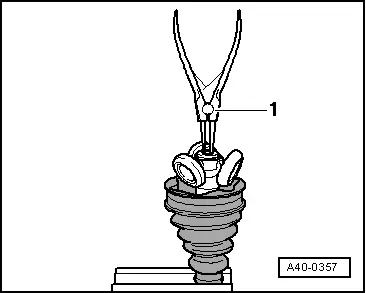

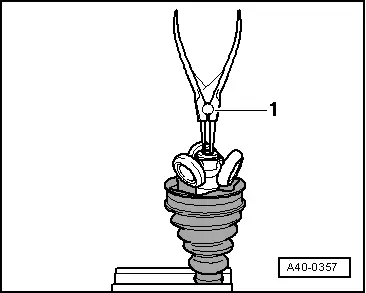

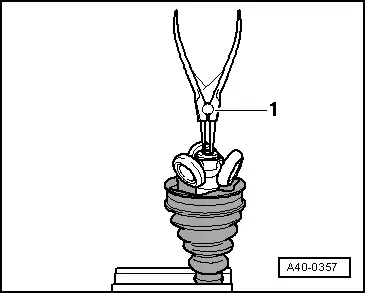

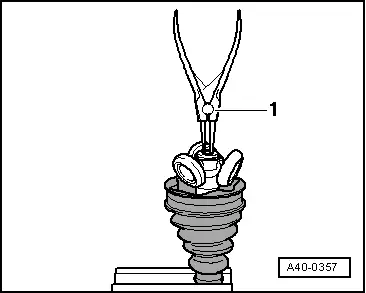

- Remove the circlip with locking ring pliers -1-.

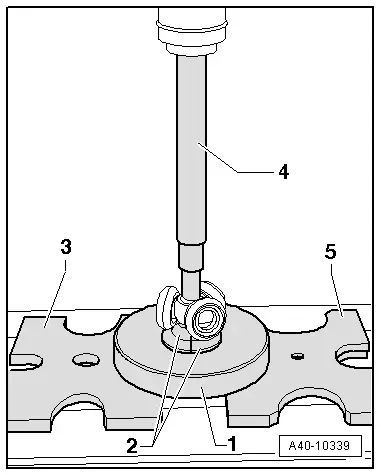

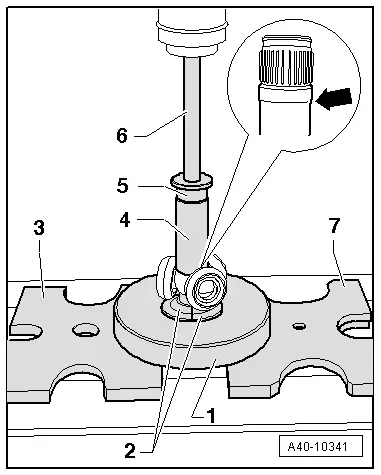

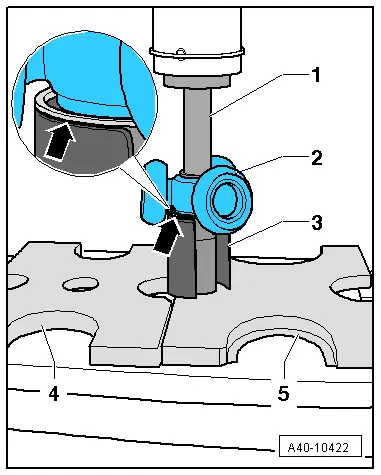

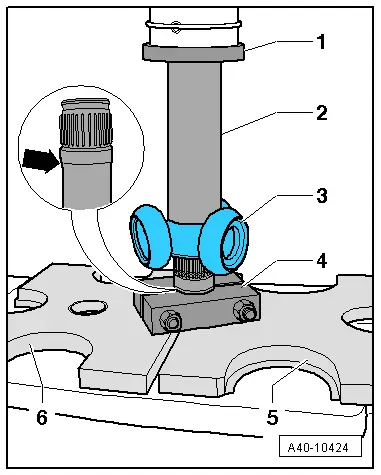

- Mount the special tools as shown.

1 - Assembly Tool -T10065/1-

2 - Triple Roller Assembly Tool -T10065/5+/6-

3 - Press Plate -VW401-

4 - Press Piece - Rod -VW408A-

5 - Press Plate -VW402-

- Triple Roller Assembly Tool -T10065/5+/6- - must touch the triple roller star base

- The Triple Roller Assembly Tool -T10065/5+/6- must not touch the rollers; move the rollers to the side if necessary.

- Press the triple roller star off the drive shaft.

- Remove the protective boot.

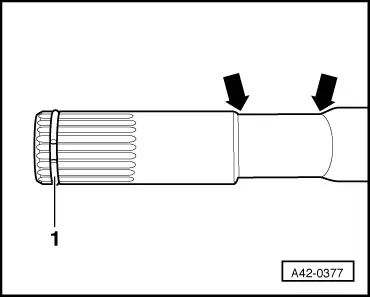

- Remove the grease on the shaft splines.

- Check the roller body and ball cage for wear.

- Clean drive axle and housing.

Assembling

- Slide on the small clamp with the CV boot.

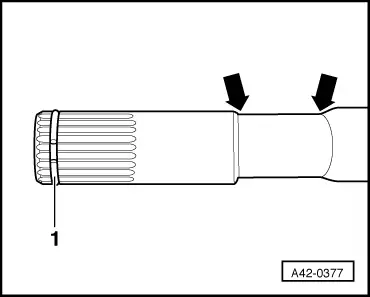

- Position the CV boot between the -arrows- on the drive axle.

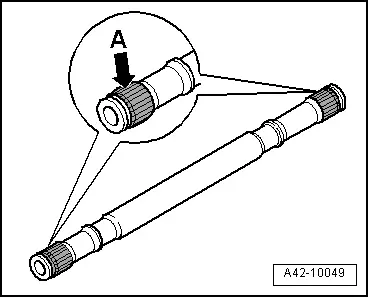

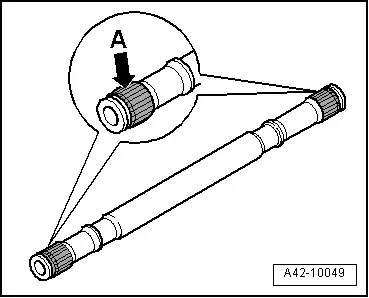

- Before installing the joint or triple roller star, splines -arrow A- must be lightly coated with grease used in joint.

- Place triple roller star on shaft according to mark and drive on until impact.

- Mount the special tools as shown.

1 - Assembly Tool -T10065/1-

2 - Triple Roller Assembly Tool -T10065/5+/6-

3 - Press Plate -VW401-

4 - Press Piece - 37mm -VW416B-

5 - Press Piece - Multiple Use -VW447H-

6 - Press Piece - Rod -VW411-

7 - Press Plate -VW402-

- Triple Roller Assembly Tool -T10065/5+/6- - must attach to the bead at the bottom of the drive axle -arrow-.

- The Triple Roller Assembly Tool -T10065/5+/6- must not touch the rollers; move the rollers to the side if necessary.

- Install the circlip with locking ring pliers -1-.

- Circlip must engage audibly, triple roller star must lie against circlip with no gap.

- Press the drive axle grease from the repair kit into the rear side of the triple roller joint.

- Lightly grease the roller body.

- Press the joint over the triple roller star using a plastic hammer in direction of -arrow-. At the same time make sure roller body does not tilt!

- Press remaining quantity of grease in protective boot.

- Make sure the protective boot is seated on the joint correctly.

- The CV boot must fit in the groove and on joint contour.

- Triple roller joint clamps, installing and tensioning. Refer to → Chapter "Clamp on Triple Roller Joint and Outer Joint, Tensioning".

Drive Axle, Disassembling and Assembling, Triple Roller Joint AAR 3700i

Special tools and workshop equipment required

- Press Plate -VW401-

- Press Plate -VW402-

- Press Piece - Rod -VW409-

- Press Piece - Multiple Use -VW412-

- Press Piece - 37mm -VW416B-

- CV Joint Press Sleeve -VW522-

- Slide Hammer Set -VW771-

- Press Block -40-204A-

- Triple Roller Assembly Tool -T40236-

- Pneumatic Hydraulic Press -VAS6654-, not illustrated

- Commercially available locking ring pliers.

Disassembling

- Clamp the drive axle horizontally in a vise with protective covers.

Note

Note

Make sure that drive axle is not damaged.

- Open clamps -arrows-.

- Slide back protective boot.

Caution

Caution

Risk of noises when driving due to a changed installation position.

For reinstallation mark the installation position of the joint to the drive axle using for example a waterproof marker.

- Guide the Triple Roller Assembly Tool -T40236- behind the joint.

- The guide pins -1- must contact the outer joint.

- Move the Triple Roller Assembly Tool -T40236- to the joint until stop by turning knurled bolts -2-.

Note

Note

- Secure the joint without play in the Triple Roller Assembly Tool -T40236-.

- Only tighten the knurled bolts hand tight.

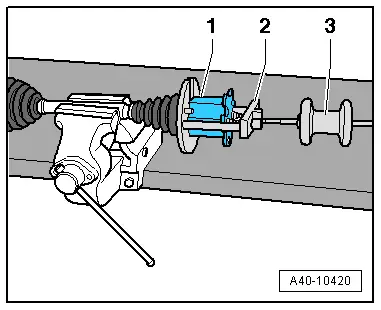

- Install the Slide Hammer Set -VW771--3- in the Triple Roller Assembly Tool -T40236--2-.

- Remove the joint -1- horizontally with the Slide Hammer Set -VW771-.

- Leave the joint in the Triple Roller Assembly Tool -T40236-.

Caution

Caution

Risk of noises when driving due to a changed installation position.

For reinstallation mark the installation position of the drive axle -1- to the triple roller star -2- using for example a waterproof marker -arrow-.

- Remove grease with lint-free cloth.

- Remove the circlip with locking ring pliers -1-.

- Mount the special tools as shown.

1 - Press Piece - Rod -VW409-

2 - Triple roller star

3 - CV Joint Press Sleeve -VW522-

4 - Press Plate -VW401-

5 - Press Plate -VW402-

- The CV Joint Press Sleeve -VW522- must contact the locking ring -arrow-. The locking ring is removed together with the triple roller star from the drive axle.

- The CV Joint Press Sleeve -VW522- must not touch the rollers; move the rollers to the side if necessary.

- Press the triple roller star off the drive shaft.

- Remove the protective boot.

- Remove the grease on the shaft splines.

- Check the roller body and ball cage for wear.

- Clean drive axle and housing.

Assembling

- Slide on the small clamp with the CV boot.

- Position the CV boot between the -arrows- on the drive axle.

- Before installing the joint or triple roller star, splines -arrow A- must be lightly coated with grease used in joint.

- Install the Press Block - 40-204A--2- as shown.

- The Press Block -40-204A- - must attach to the bead at the bottom of the drive axle -arrow-.

- Tighten the nuts -3- hand tight.

- Insert the new circlip -1- to center of splines

- Place triple roller star on shaft according to mark and drive on until impact.

- Mount the special tools as shown.

1 - Press Piece - Multiple Use -VW412-

2 - Press Piece - 37mm -VW416B-

3 - Triple roller star

4 - Press Block -40-204A-

5 - Press Plate -VW402-

6 - Press Plate -VW401-

- The Press Piece - 37mm -VW416B- larger internal diameter points to the triple roller star.

- The Press Block -40-204A- - must attach to the bead at the bottom of the drive axle -arrow-.

- The Press Block -40-204A- must not touch the rollers; move the rollers to the side if necessary.

- Install the triple roller star.

- Circlip must engage audibly, triple roller star must lie against circlip with no gap.

- Install the circlip with locking ring pliers -1-.

- Press the drive axle grease from the repair kit into the rear side of the triple roller joint.

- Lightly grease the roller body.

- Press the joint -2- over the triple roller star using a plastic hammer in direction of -arrow-. At the same time make sure roller body does not tilt!

1 - Triple Roller Assembly Tool -T40236-

- Press remaining quantity of grease in protective boot.

- Make sure the protective boot is seated on the joint correctly.

- The CV boot must fit in the groove and on joint contour.

- Triple roller joint clamp, installing and tensioning. Refer to → Chapter "Clamp on Triple Roller Joint and Outer Joint, Tensioning".