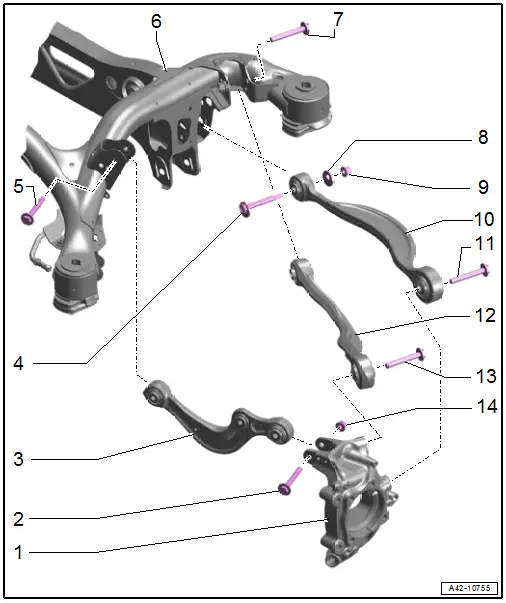

Audi Q7: Overview - Transverse Link

Audi Q7 (4M) 2016-2026 Workshop Manual / Chassis / Suspension, Wheels, Steering / Rear Suspension / Overview - Transverse Link

Upper Transverse Link

1 - Wheel Bearing Housing

2 - Bolt

- 70 Nm +180º

- Replace after removing

- Must be tightened in the curb weight position. Refer to → Chapter "Wheel Bearing at Standard Vehicle Height, Lifting Vehicles with Air Suspension".

3 - Transverse Link, Upper Front

- Removing and installing. Refer to → Chapter "Upper Transverse Link, Removing and Installing".

4 - Eccentric Bolt

5 - Bolt

- 40 Nm +180º

- Replace after removing

- Must be tightened in the curb weight position. Refer to → Chapter "Wheel Bearing at Standard Vehicle Height, Lifting Vehicles with Air Suspension".

6 - Subframe

7 - Bolt

- 70 Nm +180º

- Replace after removing

- Must be tightened in the curb weight position. Refer to → Chapter "Wheel Bearing at Standard Vehicle Height, Lifting Vehicles with Air Suspension".

8 - Eccentric Washer

9 - Nut

- 110 Nm

- Replace after removing

- Loosen and tighten using the 21 mm internal multi-point socket

- Must be tightened in the curb weight position. Refer to → Chapter "Wheel Bearing at Standard Vehicle Height, Lifting Vehicles with Air Suspension".

10 - Tie Rod

- Removing and installing. Refer to → Chapter "Tie Rod, Removing and Installing".

11 - Bolt

- 100 Nm +180º

- Replace after removing

- Must be tightened in the curb weight position. Refer to → Chapter "Wheel Bearing at Standard Vehicle Height, Lifting Vehicles with Air Suspension".

12 - Upper Rear Transverse Link

- Removing and installing. Refer to → Chapter "Rear Upper Transverse Link, Removing and Installing".

13 - Bolt

- 100 Nm +180º

- Replace after removing

- Must be tightened in the curb weight position. Refer to → Chapter "Wheel Bearing at Standard Vehicle Height, Lifting Vehicles with Air Suspension".

14 - Nut

- Replace after removing

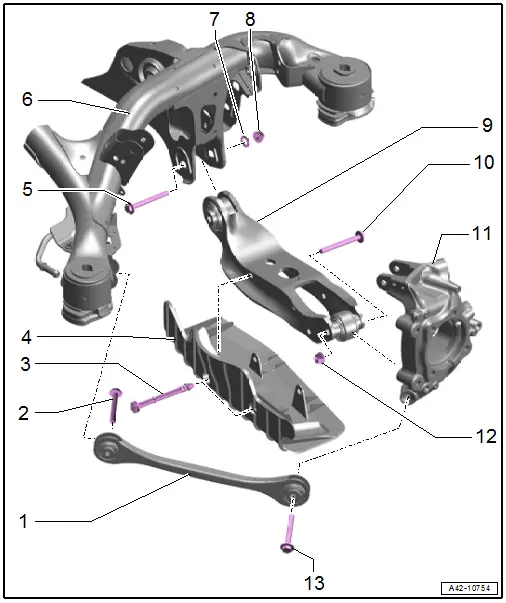

Lower Transverse Link

1 - Front Lower Transverse Link

- Removing and installing. Refer to → Chapter "Front Lower Transverse Link, Removing and Installing".

2 - Bolt

- 40 Nm +180º

- Replace after removing

- Must be tightened in the curb weight position. Refer to → Chapter "Wheel Bearing at Standard Vehicle Height, Lifting Vehicles with Air Suspension".

3 - Retaining Pin

4 - Wind Deflector

5 - Eccentric Bolt

6 - Subframe

7 - Eccentric Washer

8 - Nut

- 160 Nm

- Replace after removing

- Must be tightened in the curb weight position. Refer to → Chapter "Wheel Bearing at Standard Vehicle Height, Lifting Vehicles with Air Suspension".

- Loosen and tighten using the 21 mm 6-edge wrench

9 - Rear Lower Transverse Link

- Removing and installing. Refer to → Chapter "Rear Lower Transverse Link, Removing and Installing".

10 - Bolt

- Replace after removing

11 - Wheel Bearing Housing

12 - Nut

- 130 Nm +180º

- Replace after removing

- Must be tightened in the curb weight position. Refer to → Chapter "Wheel Bearing at Standard Vehicle Height, Lifting Vehicles with Air Suspension".

13 - Bolt

- 70 Nm +180º

- Replace after removing

- Must be tightened in the curb weight position. Refer to → Chapter "Wheel Bearing at Standard Vehicle Height, Lifting Vehicles with Air Suspension".