Audi Q7: Repair Information

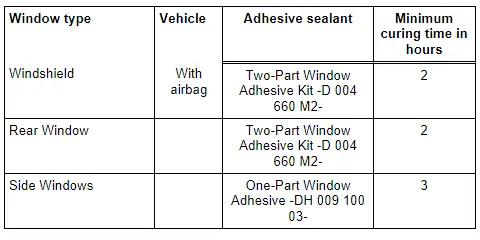

Minimum Curing Times for Bonded Windows

- For safety reasons, use only non-conductive two-part adhesive when installing windshield and rear window with the materials listed below.

- The vehicle can only be used after the minimum curing time has elapsed.

- During the minimum curing time, the vehicle must be resting at room temperature (at least 15 ºC (59 ºF) ) on a level surface.

Windows, Servicing

Special tools and workshop equipment required

- Window Repair Kit -VAS1993- or Windscreen Repair Set -VAS6092-

Windshields with stone chips can be repaired with the -VAS6092- and the -VAS1993/2-.

- These damaged areas must not exceed a certain dimension and location or lie within the field of vision.

For more usage information, refer to Operating Instructions included with each kit.

Necessary Tools and Materials for Removing and Installing

Special tools and workshop equipment required

- Cutting Tool for Bonded Windows -VAS6452-

- Cutting Tool for Bonded Windows - Wire Reel -VAS6452/1-

- Cutting Tool for Bonded Windows - Wire -VAS6452/2-

- Bonded Window Tool Kit -VAG1351-

- Bonded Window Tool Kit - Pull Handle -VAG1351/1-

- Double Suction Lifter -VAG1344-

- Window Cutter -VAG1561A-

- Blade Offset -VAG1561/10-

- Window Cutter - Universal Blade (2 pc.) -VAG1561/11-

- Window Cutter - Scraper (2 pc.) -VAG1561/7+8-

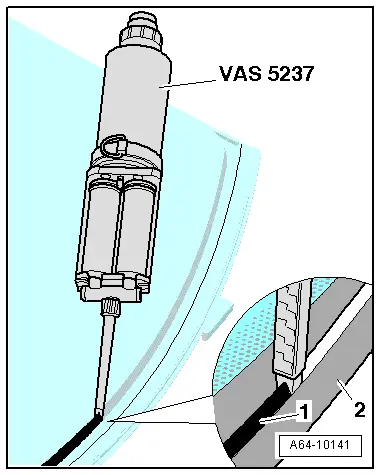

- Double Cartridge Adhesive Gun -VAS5237-

- Cartridge Gun -VAG1628-

- Cartridge Heater -VAG1939A-

Materials

- Two-Part Window Adhesive Kit -D 004 660 M2-. Refer to → Note.

- One-Part Window Adhesive -DH 009 100 A2-. Refer to → Note.

- Glass-/Paint Primer -D 009 200 02-

- Cleaning Solution -D 009 401 04-

- Applicator -D 009 500 25-

- Adhesive Remover -D 002 000 10-

- Cutting Tool for Bonded Windows - Wire -6452/2- or Cutting Wire -357 853 999-

1) Observe the minimum curing time. Refer to → Chapter "Minimum Curing Times for Bonded Windows".

2) To process this material, the -VAS5237- must be used.

3) Heat according to manufacturer's instructions using the - VAG1939 A-.

4) Small cartridge (180 ml) for sealing and/or when a 400 ml double cartridge is not sufficient.

Undamaged Window Glass, Preparing for Installation

Special tools and workshop equipment required

- Window Cutter -VAG1561 A-

- Window Cutter - Scraper -VAG1561/8-

- The adhesive surfaces must be free of dirt and grease.

- Only cut back adhesive surface just before installation.

- Do not prime or use a cleaning solution on the adhesive surface.

- When reusing the undamaged window, cut the rest of the adhesive material on the window and flange with the -VAG1561 A- and -VAG1561/8- so it is even, but do not remove it completely.

Note

Note

The remaining material acts as a base for the new adhesive sealant to be applied.

New Window Glass, Preparing for Installation

- Clean all around the adhesive surface using Cleaning Solution -D 009 401 04-.

- Wipe down the cleaned surface with dry, lint free paper.

- The adhesive surfaces must be free of dirt and grease.

- The surface must be primed before applying adhesive sealant.

- Glass/paint primer is electrically conductive and therefore must not touch the bus bar on the rear window defogger, for example.

- The window glass must be inserted within 15 minutes of applying the sealant.

- Apply the Glass/Paint Primer -D 009 200 02- as described in the following.

Note

Note

The ceramic layer on new windows is not primer.

Primer, Applying:

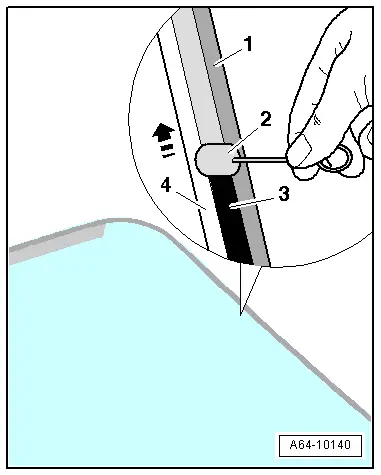

- Using the applicator -2-, apply the glass/paint primer -3- evenly and in one stroke near the molding -1- on the window glass -4-.

- Begin applying with a saturated piece of felt.

- Primer width approximately 20 mm.

- The glass/paint primer must be centered to the adhesive bead.

- Drying time: 10 minutes

Applying Adhesive:

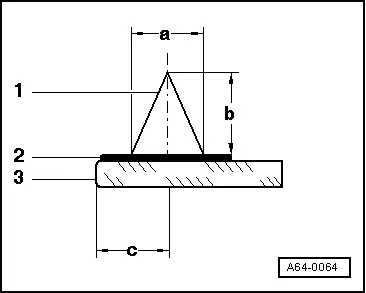

Dimensions for adhesive application:

1 - Adhesive Bead

2 - Glass/Paint Primer

3 - Washer

- Dimension -a- = 6.5 mm

- Dimension -b- = 10 mm

- Dimension -c- = note the different distances to the window edge. Refer to → Chapter "Overview - Windshield", → Chapter "Overview - Rear Side Window" and → Chapter "Overview - Rear Window".

Note

Note

The adhesive bead cross section is determined by the nozzle tip opening and the rate of application.

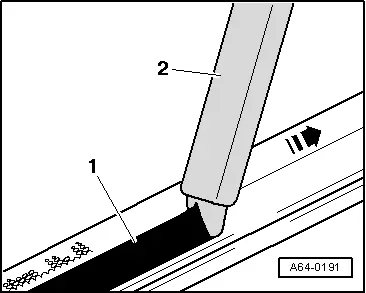

- Position the entire surface of the nozzle -2- on the window.

- Application direction -arrow- for the adhesive bead -1-.

- Apply adhesive sealant -1- all around the window -2- as shown.

- Insert the windshield or rear window into the opening for the window using two suction lifters for assistance.

- The window glass must be installed within 15 minutes or the adhesive sealant will not bond correctly.

Body Flange, Preparing for Installation

- The adhesive surfaces must be free of dirt and grease.

- Only cut back adhesive surface just before installation.

- Cut back the residue on the body flange with a cutting blade just before installing the window glass, but do not remove all of it.

Note

Note

The residue acts as a base for the adhesive sealant to be applied.

- If the window glass flange was damaged, repaired or replaced, the paint structure must be repaired and if necessary, the corrosion protection must be reapplied..

- First clean the repaired area with Cleaning Solution -D 009 401 04- and then apply the Glass/Paint Primer -D 009 200 02-.

Adhesive, Cleaning if Contaminated

Adhesive Remover -D 002 000 10- is recommended as a cleaning solution. Follow all safety precautions when processing.

- When cleaning from inside the vehicle interior, do not press out on the window that was just installed.

Paint Surfaces, Cleaning

- First clean the painted surface with a dry cloth. Remove residual adhesive with Adhesive Remover -D 002 000 10-.

Plastic Trim Panels, Cleaning

- Let the adhesive sealant harden (approximately 1 hour) and then remove it.