Audi Q7: Tower Brace, Removing and Installing

Tower Brace Additional Reinforcement, Removing and Installing, Q7 without High-Voltage System

Special tools and workshop equipment required

- Pry Lever -80-200-

- Torque Wrench 1331 5-50Nm -VAG1331-

Removing

- Remove the plenum chamber cover. Refer to → Body Exterior; Rep. Gr.50; Bulkhead; Plenum Chamber Cover, Removing and Installing.

- Remove the Engine Control Module -J623- from the bracket and set aside. Refer to → 6-Cyl. TDI Common Rail 3,0l 4V Motor (EA 897 Gen I); Rep. Gr.23; Engine Control Module; Engine Control ModuleJ623, Removing and Installing or → 6-Cylinder Direct Injection 3.0L 4V TFSI Supercharged Engine; Rep. Gr.24; Engine Control Module; Engine Control ModuleJ623, Removing and Installing.

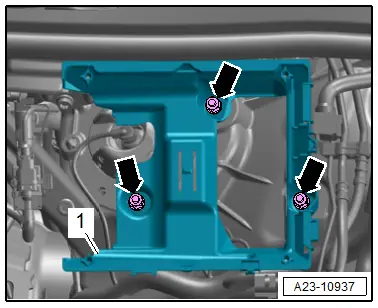

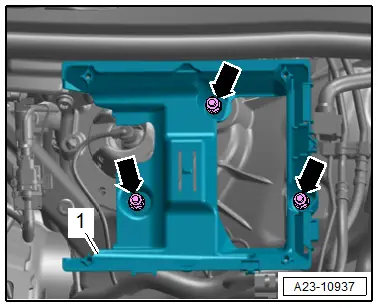

- Remove the nuts -arrows- and push the bracket -1- for the engine control module slightly forward.

- Unclip the left and right cover from the bulkhead. Refer to → Body Exterior; Rep. Gr.50; Bulkhead; Overview - Bulkhead.

- Remove the right E-Box from the bulkhead and push it slightly forward. Refer to → Electrical Equipment; Rep. Gr.97; Relay Panels, Fuse Panels and E-Boxes.

- Remove the air filter housing. Refer to → Rep. Gr.23; Air Filter; Air Filter Housing, Removing and Installing or → Rep. Gr.24; Air Filter; Air Filter Housing, Removing and Installing.

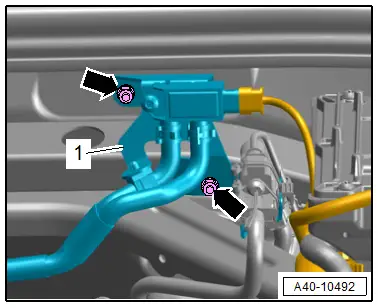

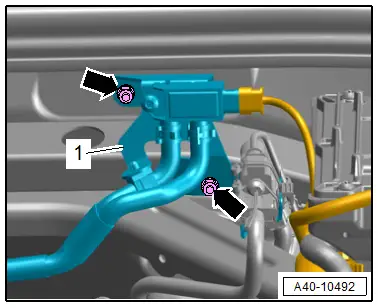

- If equipped, remove the nuts -arrows- and move the bracket -1- for the Differential Pressure Sensor -G505- to the side.

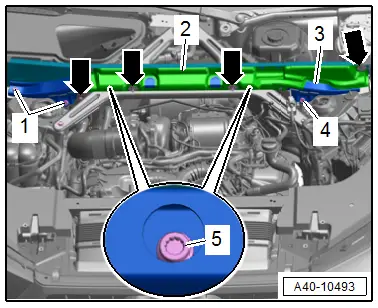

- Loosen the clamps -arrows- with the Pry Lever -80-200- and pivot the trim panel -2- upward.

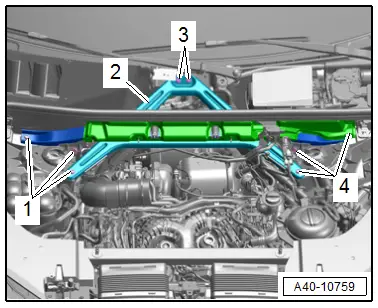

- Remove the bolts -1, 4 and 5- and remove the additional reinforcement -3- with the plenum chamber bulkhead.

Installing

Install in reverse order of removal and note the following:

- Install the air filter housing. Refer to → Rep. Gr.23; Air Filter; Air Filter Housing, Removing and Installing or → Rep. Gr.24; Air Filter; Air Filter Housing, Removing and Installing.

- Install the plenum chamber cover. Refer to → Body Exterior; Rep. Gr.50; Bulkhead; Plenum Chamber Cover, Removing and Installing.

Tightening Specifications

- Refer to → Chapter "Overview - Suspension Strut and Upper Control Arm"

- Refer to → Electrical Equipment; Rep. Gr.97; Relay Panels, Fuse Panels and E-Boxes

- Refer to → Rep. Gr.23; Heated Oxygen Sensor; Overview - Heated Oxygen Sensor.

Tower Brace, Removing and Installing, Q7 without High-Voltage System

Special tools and workshop equipment required

- Torque Wrench 1331 5-50Nm -VAG1331-

Removing

- Remove the additional reinforcement for the tower brace. Refer to → Chapter "Tower Brace Additional Reinforcement, Removing and Installing, Q7 without High-Voltage System".

- Free up the wires.

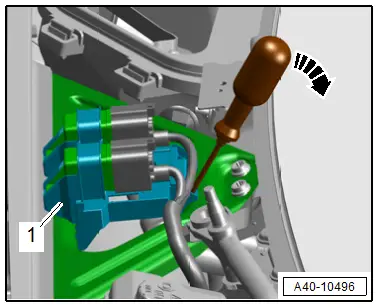

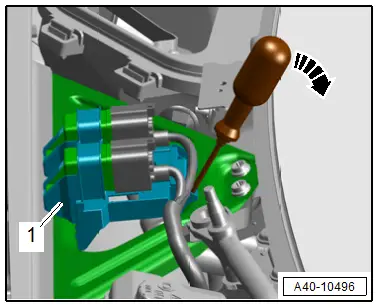

- Release the catches with a screwdriver in direction of -arrow- and remove the bracket -1- for the relay and control module and set aside.

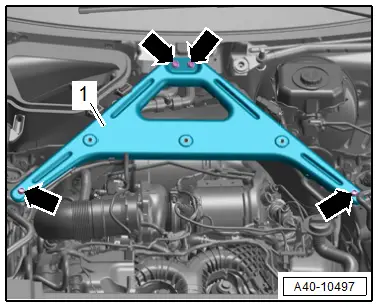

- Remove the bolts -arrows- and remove the tower brace -1-.

Installing

Install in reverse order of removal and note the following:

- Install the additional support for the tower brace. Refer to → Chapter "Tower Brace Additional Reinforcement, Removing and Installing, Q7 without High-Voltage System".

Tightening Specifications

- Refer to → Chapter "Overview - Suspension Strut and Upper Control Arm"

Tower Brace with Additional Reinforcement, Removing and Installing, Q7 e-tron

Special tools and workshop equipment required

- Pry Lever -80-200-

- Torque Wrench 1331 5-50Nm -V.A.G 1331-

Removing

- Remove the plenum chamber cover. Refer to → Body Exterior; Rep. Gr.50; Bulkhead; Plenum Chamber Cover, Removing and Installing.

- Remove the Engine Control Module -J623- from the bracket and set aside. Refer to → 6-Cyl. TDI Common Rail 3,0l 4V Motor (EA 897 Gen I); Rep. Gr.23; Engine Control Module; Engine Control ModuleJ623, Removing and Installing or → 6-Cylinder Direct Injection 3.0L 4V TFSI Supercharged Engine; Rep. Gr.24; Engine Control Module; Engine Control ModuleJ623, Removing and Installing.

- Remove the nuts -arrows- and push the bracket -1- for the engine control module slightly forward.

- Unclip the left and right cover from the bulkhead. Refer to → Body Exterior; Rep. Gr.50; Bulkhead; Overview - Bulkhead.

- Remove the right E-Box from the bulkhead and push it slightly forward. Refer to → Electrical Equipment; Rep. Gr.97; Relay Panels, Fuse Panels and E-Boxes.

- Remove the air filter housing. Refer to → Rep. Gr.23; Air Filter; Air Filter Housing, Removing and Installing or → Rep. Gr.24; Air Filter; Air Filter Housing, Removing and Installing.

- Remove the nuts -arrows- and move the bracket -1- for the Differential Pressure Sensor -G505- to the side.

- Release the catches with a screwdriver in direction of -arrow- and remove the bracket -1- for the relay and control module and set aside.

- Remove the bolts -1, 3 and 4- and remove the tower brace -2- with additional reinforcement and plenum chamber end plate.

Installing

Install in reverse order of removal and note the following:

- Install the air filter housing. Refer to → Rep. Gr.23; Air Filter; Air Filter Housing, Removing and Installing or → Rep. Gr.24; Air Filter; Air Filter Housing, Removing and Installing.

- Install the plenum chamber cover. Refer to → Body Exterior; Rep. Gr.50; Bulkhead; Plenum Chamber Cover, Removing and Installing.

Tightening Specifications

- Refer to → Chapter "Overview - Suspension Strut and Upper Control Arm"

- Refer to → Electrical Equipment; Rep. Gr.97; Relay Panels, Fuse Panels and E-Boxes

- Refer to → Rep. Gr.23; Heated Oxygen Sensor; Overview - Heated Oxygen Sensor.