Audi Q7: Disposal

Front Gas-Filled Shock Absorbers, Venting and Draining

Special tools and workshop equipment required

- Hand drill

- 3 mm diameter drill bit.

- 6 mm diameter drill bit

- Oil collecting container

- Protective Eyewear

Procedure

- Secure gas-filled shock absorber vertically in vise, with piston rod facing down.

WARNING

WARNING

Risk of eye injury.

Wear protective eyewear!

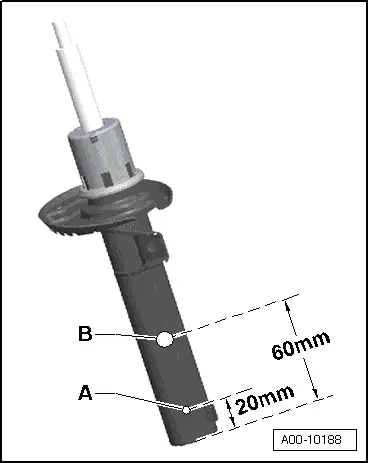

- Drill a 3 mm hole -A- through the shock absorber outer tube.

Note

Note

Gas escapes when drilling.

- Continue drilling until the tube inside is drilled through (approximately 25 mm deep).

- Drill a second 6 mm hole -B- through the outer and inner shock absorber tubes.

- Hold the shock absorber over an appropriate container for catching oil and move the piston rod repeatedly through the entire stroke until no more oil flows out.

Rear Gas-Filled Shock Absorbers, Venting and Draining

Special tools and workshop equipment required

- Hand drill

- 3 mm diameter drill bit.

- 6 mm diameter drill bit

- Oil collecting container

- Protective Eyewear

Procedure

- Secure the gas-filled shock absorber vertically in vise, with piston rod facing down.

WARNING

WARNING

Risk of eye injury.

Wear protective eyewear!

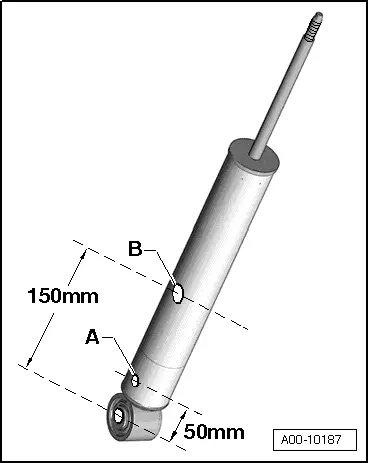

- Drill a 3 mm hole -A- through the shock absorber outer tube.

Note

Note

Gas escapes when drilling.

- Continue drilling until the tube inside is drilled through (approximately 25 mm deep).

- Drill a second 6 mm hole -B- through the outer and inner shock absorber tubes.

- Hold the shock absorber over an appropriate container for catching oil and move the piston rod repeatedly through the entire stroke until no more oil flows out.

Front Air Suspension Strut, Emptying

Procedure

- Remove the air spring: front. Refer to → Chapter "Suspension Strut, Removing and Installing"; rear. Refer to → Chapter "Shock Absorber, Removing and Installing".

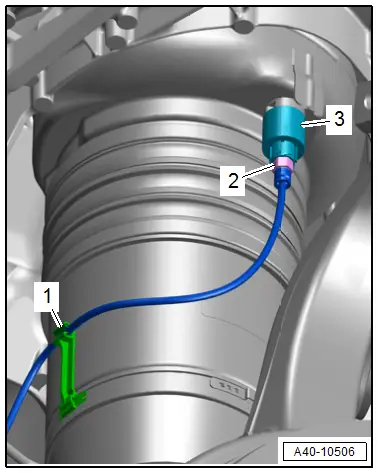

- Release from the residual pressure retaining valve air spring -3- and allow the air pressure to escape.

- Dispose of the air spring.

Note

Note

- The front air spring is shown installed.

- Ignore -1 and 2-.

Pressure Reservoir, Emptying

Procedure

- Connect the Vehicle Diagnostic Tester.

- Switch the ignition on.

- Select and start the Diagnostic operating mode.

- Select the Test plan tab.

- Select the button Individual tests and select the following tree structures one after the other:

- Suspension

- Suspension control

- 01 - OBD-capable systems

- 74 - Drivetrain Control Module J775

- 74 - Drivetrain Control Module Functions

- 74 - Complete basic setting

- Start the selected program and follow the instructions in the display of the Vehicle Diagnostic Tester.

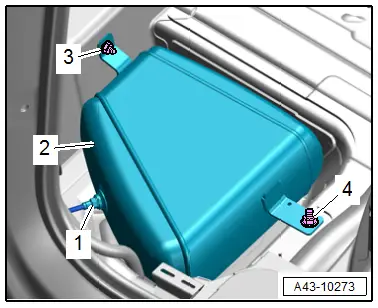

- Slowly loosen air line -1- on pressure reservoir -2- and allow air pressure to come down. After the air pressure has escaped, remove the air line.

- Remove and dispose of the pressure reservoir. Refer to → Chapter "Pressure Reservoir, Removing and Installing".

Note

Note

Ignore -3 and 4-.

Special Tools

Special tools and workshop equipment required

- Tensioning Strap -T10038-

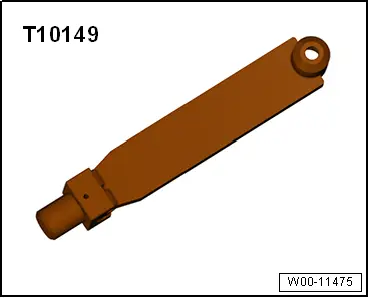

- Engine/Gearbox Jack Adapter - Wheel Hub Support -T10149-

- Engine and Gearbox Jack -VAS6931-