Audi Q7: Rear Brake Caliper

Overview - Rear Brake Caliper

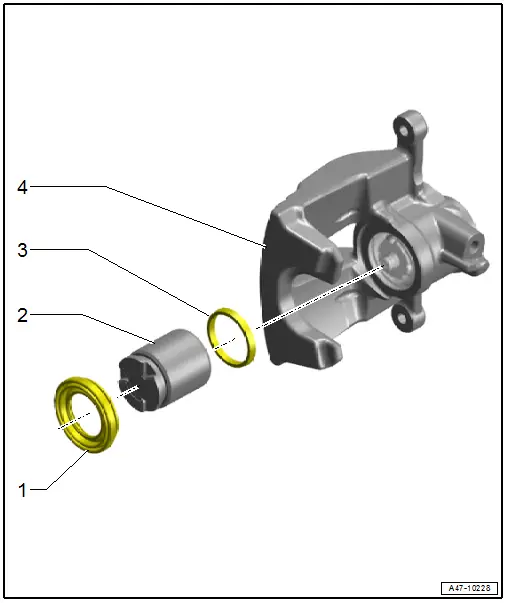

1 - Protective Cap

- Refer to → Chapter "Brake Caliper Piston, Removing and Installing"

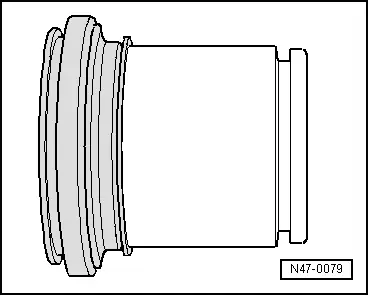

2 - Brake Caliper Piston

- Refer to → Chapter "Brake Caliper Piston, Removing and Installing"

- Thinly coat with Lithium Grease -G 052 150 A2-

3 - Gasket

- Refer to → Chapter "Brake Caliper Piston, Removing and Installing"

4 - Brake Caliper

Brake Caliper Piston, Removing and Installing

Special tools and workshop equipment required

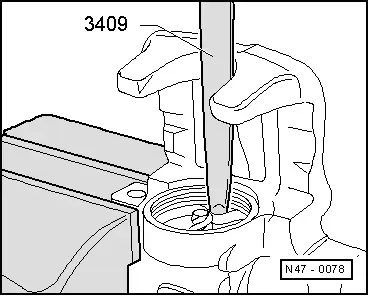

- Trim Removal Wedge -3409-

Removing

- The brake caliper is removed. Refer to → Chapter "Brake Caliper, Replacing".

- The parking brake motor is removed. Refer to → Chapter "Left and Right Parking Brake Motor - V282-/-V283-, Removing and Installing".

Note

Note

- Install the entire repair kit when servicing.

- To clean the brakes only use mineral spirits.

- Thinly coat the brake cylinder, brake caliper piston and seal with Lithium Grease -G 052 150 A2-.

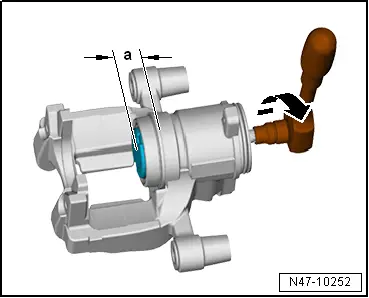

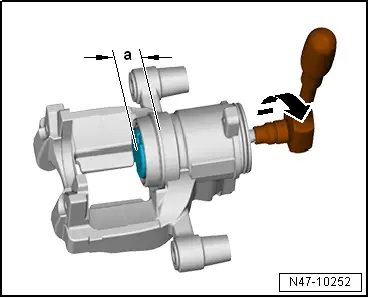

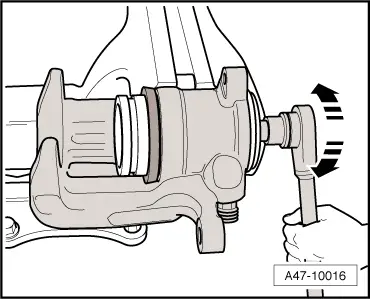

- Using an 8 mm internal multi-point socket, turn the spindle counter-clockwise -arrow-. As a result, the thrust nut pushes the brake caliper piston out of the brake caliper.

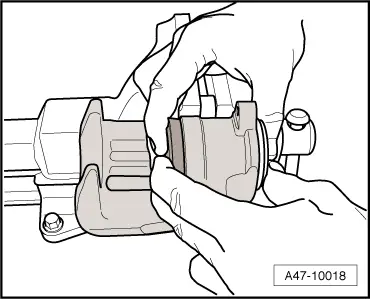

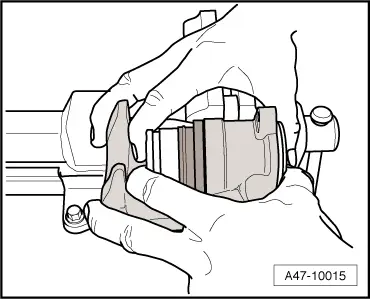

- Remove the brake caliper piston with the protective cap from the brake caliper.

- Remove the gasket using the Trim Removal Wedge -3409-.

- Clean the surfaces on the brake caliper piston and gasket only with mineral spirits and then dry.

Installing

- Thinly coat the brake caliper piston and the gasket with Lithium Grease -G 052 150 A2- before installing.

- Insert the gasket into the brake caliper.

- Place the protective cap with outer sealing lip on the brake caliper piston.

- Turn the thrust nut far enough onto the spindle so that the dimension -a- = 15 mm is reached.

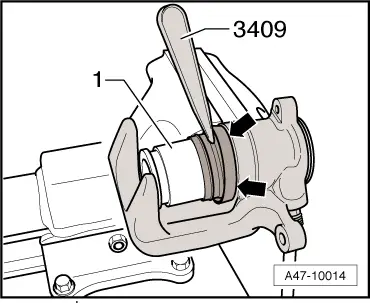

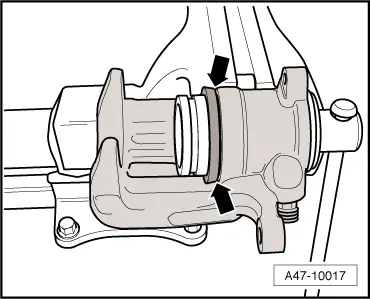

- Insert the inner sealing lip of the protective cap into the groove -arrows- in the brake caliper using the Trim Removal Wedge -3409-.

- Slide the brake caliper piston -1- onto the thrust nut, which is only possible in four positions.

- Carefully press the brake caliper piston into the brake caliper by moving the brake caliper piston.

- Press the brake caliper piston far enough into the brake caliper until it touches the thrust nut.

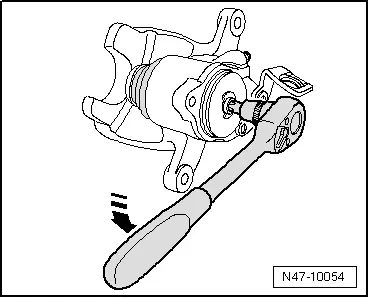

- Carefully turn the spindle clockwise in direction of -upper arrow- until the thrust nut is at the stop.

- The protective cap must fully contact the brake caliper -arrows-.

- Press the brake caliper piston into the brake caliper by hand.

- Outer sealing lip of protective cap will then engage in the brake caliper piston groove.