Audi Q7: Roof Molding/Roof Railing

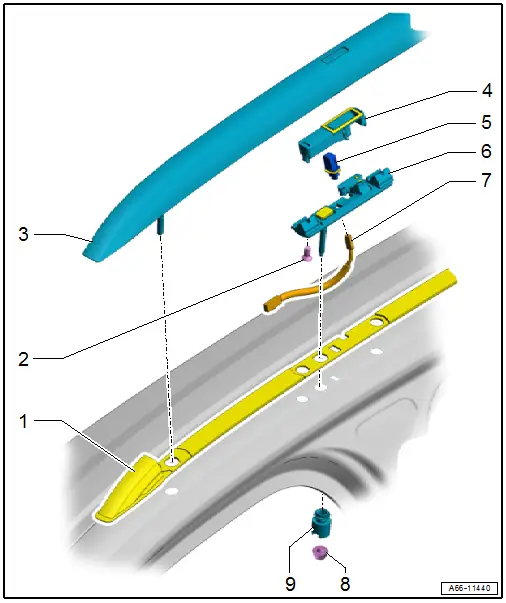

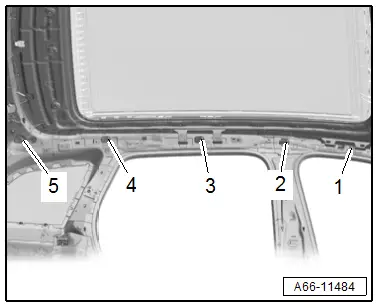

Overview - Roof Railing

1 - Seal

- Replace if damaged

2 - Bolt

- 8 Nm

- Quantity: 2

3 - Roof Railing

- Removing and Installing. Refer to → Chapter "Roof Railing, Removing and Installing".

4 - Housing Upper Section

5 - Roof Rack Recognition Sensor -G625-

6 - Housing Lower Section

7 - Wire

8 - Nut

- Quantity: 4

- Insert with locking fluid. Refer to the Parts Catalog.

- Tightening specification and sequence. Refer to → Fig.

9 - Lifter

- 0.5 Nm

- Quantity: 4

- Removing and Installing. Refer to → Chapter "Balancing Element, Removing and Installing".

- Install with locking compound. Refer to the Parts Catalog for the locking compound.

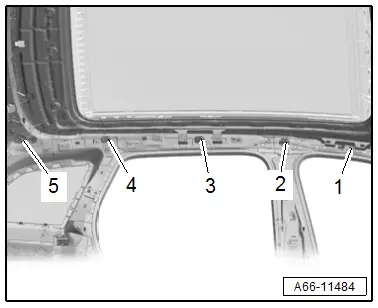

Roof Railing - Tightening Specification and Sequence

- Tighten the nuts to 10 Nm in the sequence -2, 3, 4, 5 and 1-.

Roof Railing, Removing and Installing

- Follow the safety precautions. Refer to → Body Interior; Rep. Gr.00; Safety Precautions; Safety Precautions when Working on Pyrotechnic Components.

Special tools and workshop equipment required

- Locking fluid. Refer to the Parts Catalog.

Removing

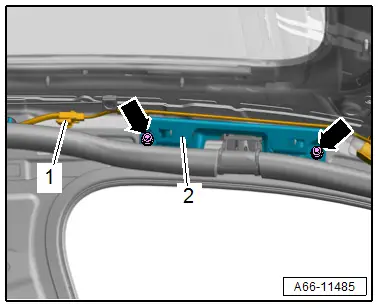

- Remove the head curtain airbag igniter from the body. The head curtain airbag remains installed. Refer to → Body Interior; Rep. Gr.69; Head Curtain Airbags; Head Curtain Airbag with Igniter, Removing and Installing.

- Disconnect the connector -1-.

- Remove the nuts -arrows- and move the bracket -2- to the side.

- Remove the nuts -1 to 5-

- Remove the roof railing upward.

Installing

- Clean the threaded pin threads on the roof railing with a wire brush.

- Check the seal for damage and replace if necessary.

- Carefully remove any remaining locking fluid from the nut threads that are installed with locking fluid using a thread tap.

Note

Note

There is no cleaning procedure, since there is a risk of the threaded pins shearing off when disassembling again.

- Insert the roof railing with the guide pin into the mount on the vehicle roof.

- Install the nuts with locking fluid and tighten.

Further installation is the reverse order of removal.

Tightening Specifications

- Refer to → Fig. "Roof Railing - Tightening Specification and Sequence"

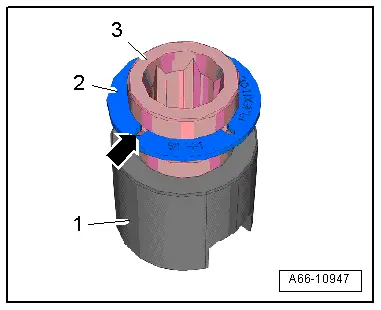

Balancing Element, Removing and Installing

Special tools and workshop equipment required

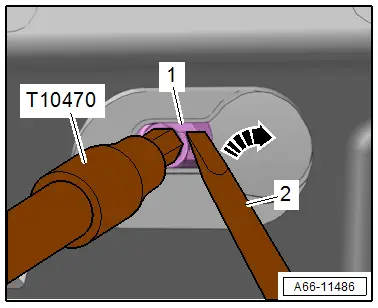

- Socket - Torx T50 -T10470-

Removing

- Remove the roof railing. Refer to → Chapter "Roof Railing, Removing and Installing".

- Remove the adjusting screw in the lifter -1- several turns with the -T10470- by counterholding with a screwdriver -2-.

- Remove the lifter from the roof opening -arrow-.

Installing

- Clean the adjusting screw threads -3- with a wire brush.

- Clean the threaded hole of the lifter -1- of locking compound residue with a thread tap.

- Check the stop washer -2- for damage and replace the lifter, if necessary.

- The stop washer must sit in the groove -arrow-.

- Install the adjusting screw with locking fluid in the lifter.

- Insert the lifter into the roof opening and secure it with the adjusting screw.

Further installation is the reverse order of removal.