Audi Q7: Standard Vehicle Height, Readapting

The air suspension system responds automatically to changes in the vehicle level and equals these out.

The vehicle level can change in the following situations:

- Trailer Mode

- Different load conditions; vehicle empty, vehicle partially or fully loaded

For versions with air suspension system the 'level sensor end stops' and the 'level sensor zero position' must be newly adapted, when:

- A level sensor is removed and reinstalled

- A level sensor was replaced

- An air spring strut on the front axle was replaced

- An air spring on the rear axle was replaced

Requirements

- The vehicle must be standing on an even surface.

- The vehicle may not be loaded.

Procedure

- Connect the Vehicle Diagnostic Tester.

- Switch the ignition on.

- Select and start the Diagnostic operating mode.

- Select the Test plan tab.

- Select the button Individual tests and select the following tree structures one after the other:

- Suspension

- Suspension control

- 01 - OBD-capable systems

- 74 - Drivetrain Control Module J775

- 74 - Drivetrain Control Module Functions

- 74 - Complete basic setting

- Start the selected program and follow the instructions in the display of the Vehicle Diagnostic Tester.

- The standard vehicle height is reached.

If the standard vehicle height is readapted, the following work must be performed:

- Adjust the headlamps. Refer to → Electrical Equipment; Rep. Gr.94; Headlamps; Headlamp, Adjusting.

- Driver Assistance Systems Front Camera, Calibrating. Refer to → Chapter "Driver Assistance Systems Front Camera, Calibrating".

- Infrared System, Calibrating. Refer to → Chapter "Infrared System, Calibrating".

Air Suspension System, Filling and Bleeding

Bleeding

- Connect the Vehicle Diagnostic Tester.

- Switch the ignition on.

- Select and start the Diagnostic operating mode.

- Select the Test plan tab.

- Select the button Individual tests and select the following tree structures one after the other:

- Suspension

- Suspension control

- 01 - OBD-capable systems

- 74 - Drivetrain Control Module J775

- 74 - Drivetrain Control Module Functions

- 74 - Complete basic setting

- Start the selected program and follow the instructions in the display of the Vehicle Diagnostic Tester.

Filling

- To fill proceed in the same way under

- Suspension

- Suspension control

- 01 - OBD-capable systems

- 74 - Drivetrain Control Module J775

- 74 - Drivetrain Control Module Functions

- 74 - Complete basic setting

Drivetrain Control Module -J775-, Removing and Installing

Removing

- Remove the center console trim panels. Refer to → Body Interior; Rep. Gr.68; Center Console; Overview - Center Console; Overview - center console, support/cover.

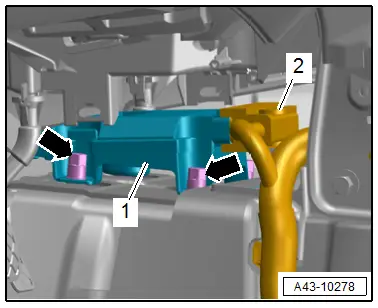

- Disconnect the connector -1-.

- Remove the left and right nuts -arrows- and remove the Drivetrain Control Module -J775-.

Installing

Install in reverse order of removal and note the following:

- After installing a new Drivetrain Control Module -J775- activate the control module.

- Connect the Vehicle Diagnostic Tester.

- Switch the ignition on.

- Select and start the Diagnostic operating mode.

- Select the Test plan tab.

- Select the button Individual tests and select the following tree structures one after the other:

- Suspension

- Suspension control

- 01 - OBD-capable systems

- 74 - Drivetrain Control Module J775

- 74 - Drivetrain Control Module Functions

- 74 - Control module, replacing

- Start the selected program and follow the instructions in the display of the Vehicle Diagnostic Tester.

- Readapt the standard vehicle height. Refer to → Chapter "Standard Vehicle Height, Readapting".

Tightening Specifications

- Refer to → Fig. " Drivetrain Control Module -J775- "

Level Control System Compressor Electronics -J1135-, Removing and Installing

Removing

- Switch off the ignition.

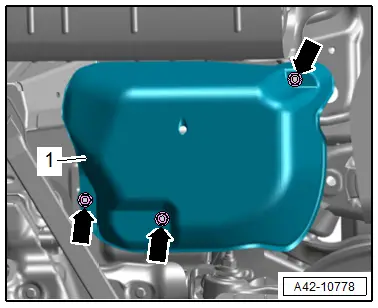

- Remove the nuts -arrows-, and remove the cover -1- for the air supply unit.

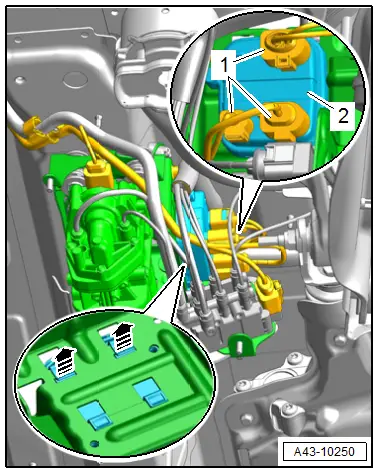

- Disconnect the connectors -1-.

- Carefully release the catches in direction of -arrows- and remove the control module -2- upward from the bracket.

Installing

Install in reverse order of removal.